- The Importance of Hot Forming Die Design: Key Considerations to Keep in Mind

By:Admin

One company that has been at the forefront of hot forming die design is {}. Founded in 1990, {} has been a leading manufacturer of hot forming dies for various industries. The company's commitment to quality, innovation, and customer satisfaction has made it a trusted partner for many businesses around the world.

The design of hot forming dies is a complex and intricate process that requires a deep understanding of materials, heat treatment, and mechanical properties. {} has a team of experienced and skilled engineers and designers who are well-versed in the latest technologies and techniques in hot forming die design. Through continuous research and development, the company has been able to develop cutting-edge die designs that meet the evolving needs of its customers.

One of the key factors in hot forming die design is material selection. {} utilizes advanced simulation and modeling software to analyze different materials and their behavior under high temperature and pressure. This allows the company to choose the most suitable material for each specific application, ensuring the durability and performance of the hot forming dies.

In addition to material selection, the design of cooling systems is also crucial in hot forming die design. {} employs state-of-the-art cooling solutions that help to control the temperature of the dies during the forming process, thus preventing thermal distortion and ensuring the accuracy of the final components.

Furthermore, {} has been a pioneer in the integration of additive manufacturing techniques in hot forming die design. By leveraging 3D printing technology, the company is able to create complex geometries and intricate cooling channels that were previously impossible with traditional manufacturing methods. This allows {} to offer its customers highly customized and innovative hot forming die designs that meet their specific requirements.

Another area in which {} excels is in the optimization of die heating and thermal management. Through advanced thermal analysis and simulation, the company is able to achieve uniform heating and precise temperature control in the hot forming dies, leading to improved forming accuracy and shorter cycle times.

Moreover, {} understands the importance of efficient and cost-effective production processes. The company's hot forming die designs are not only optimized for performance but also for manufacturability. With a keen eye on reducing lead times and production costs, {} ensures that its customers can benefit from high-quality hot forming dies without compromising on efficiency and affordability.

In conclusion, hot forming die design is a critical aspect of modern manufacturing, and {} has been a leading force in this field. Through its dedication to quality, innovation, and customer satisfaction, the company has established itself as a trusted partner for businesses looking for advanced and reliable hot forming die designs. With a focus on material selection, cooling systems, additive manufacturing, thermal management, and cost-effective production processes, {} continues to push the boundaries of hot forming die design, meeting the evolving needs of its customers and contributing to the advancement of various industries.

Company News & Blog

Hydraulic Workshop Presses for Various Industrial Uses: L Series from 80 to 300 Tonnes

Machines, Second Hand Machines, Guillotine Motorized Workshop Presses, Bending Machines, Shears, Hydraulic Bending Machines, Hydraulic Presses, Press-Brakes.When it comes to working with metal, machinery is essential. From bending to punching, cutting to shaping, there are a variety of industrial machines that can help you achieve precision results in your workshop. Whether you're starting a new business or upgrading your existing machinery, it's important to consider the types of machines that best suit your needs. In this blog, we'll take a closer look at some of the key industrial machines available for your workshop, including machine screw second punch machines and other valuable tools.One type of machinery that many workshops rely on is the hydraulic press. Hydraulic presses can be used for a variety of tasks, including punching, deep-drawing, fretwork, and straightening. The latest generation of hydraulic presses, such as the L series from 80 to 300 tonnes (without mentioning the brand name), now feature a range of versatile uses, including the ability to install moulds and dies. With a wide range of equipment for bending, punching, and other tasks, the L series hydraulic presses are ideal for businesses that require flexibility and accuracy in their workshop machinery.Another essential tool in any metalworking workshop is the shears. Shearing machines can be used to cut a variety of materials, including sheet metal, steel plate, and other types of metal that require precise cuts. Hydraulic shears are particularly useful due to the level of control that they offer, allowing you to ensure straight, clean cuts every time.Bending machines are also an important tool for metalworkers. Hydraulic bending machines, in particular, are highly versatile and can be used to bend a wide range of metals, including steel, aluminum, and copper. These machines can be used to create a variety of shapes, from simple curves to complex, multi-bend configurations. With the ability to bend both thick and thin metals, hydraulic bending machines are an essential tool for any metalworking workshop.When it comes to second hand machines, purchasing used equipment can be a cost-effective solution for businesses on a budget. While it's important to ensure that any used machinery is in good condition and has been properly maintained, second hand machines can offer excellent value for money. This is particularly true for businesses that don't require the latest technology or advanced features, such as those needed for highly specialized tasks.In conclusion, whether you're running a small metalworking business or a larger workshop, investing in quality machinery is essential. From hydraulic presses to shears, bending machines, and more, there are a wide range of tools available to help you achieve your desired results. By carefully selecting the right machinery for your needs - and keeping your eyes open for cost-effective second hand options - you can ensure that your workshop is fully equipped to handle any metalworking challenge. And with the addition of powerful tools like machine screw second punch machines, you'll be able to take on even the most complex projects with ease.

Discover the Fascinating World of Pan Head Screws: The Second Punch Unveiled!

Title: Increased Efficiency and Reliability with the Revolutionary Second Punch Pan Head ScrewIntroduction:In today's fast-paced and technologically advanced world, businesses and individuals rely on efficient and reliable hardware solutions to support their operations. Innovative advancements in the manufacturing industry continue to revolutionize the way we approach construction and assembly processes. In line with these developments, the introduction of the Second Punch Pan Head Screw by a leading industry player brings forth a game-changing solution that promises enhanced performance and ease of use.Body:I. Background on Pan Head Screws:Pan head screws have been the go-to choice for numerous industries due to their versatile design and easy application. Historically, they have offered a great balance between strength, durability, and aesthetics. However, as industries evolve and aim for higher efficiency, there is an increasing demand for improved screw fastening solutions.II. The Second Punch Pan Head Screw:The introduction of the Second Punch Pan Head Screw marks a significant milestone in the field of fastening technology. Developed by cutting-edge components manufacturer, the screw incorporates innovative features that elevate its performance to a whole new level.The Second Punch Pan Head Screw boasts an advanced double-punch design, which optimizes the screw's ability to penetrate various materials with precision. This technology results in a faster and more effortless installation process, ultimately reducing production time and cost.III. Enhanced Features and Benefits:1. Increased Strength and Stability: The Second Punch Pan Head Screw's unique design ensures a secure and reliable connection between fastened components. Its improved thread pattern maximizes grip strength, reducing the risk of loosening over time.2. Versatile Application: With its ability to handle multiple materials, including wood, metal, and plastics, this screw is a versatile solution suitable for various industries. Whether it’s construction, furniture manufacturing, or aerospace, the Second Punch Pan Head Screw proves to be a valuable asset.3. Convenient Assembly: The screw's innovative double punch significantly reduces installation effort. The improved penetration capability allows for better acceptance on countersinks and minimizes the risk of stripping or damage to materials during the fastening process.4. Aesthetic Appeal: Keeping up with evolving design trends, the Second Punch Pan Head Screw offers a sleek and visually pleasing finish. This characteristic ensures an attractive and seamless appearance in applications where aesthetics matter.IV. Industry Impact:The introduction of the Second Punch Pan Head Screw has already begun to make waves across various industries. Its superior performance and ease of use have resulted in increased productivity and worker satisfaction. Industries such as construction, furniture manufacturing, and automotive assembly have reported more seamless production processes and reduced assembly times, leading to cost savings and improved overall efficiency.V. Future Prospects and Conclusion:As demand for efficient and reliable fastening solutions continues to rise, the Second Punch Pan Head Screw is set to play a significant role in shaping future manufacturing processes. Its advanced features and benefits make it an ideal choice for businesses looking to improve productivity, reduce costs, and ensure long-lasting, secure connections.With its versatile applicability and innovative design, the Second Punch Pan Head Screw is a testament to the successful integration of technology in traditional hardware solutions. As the industry seeks constant improvement, it is pivotal to embrace such advancements that lay the foundation for increased efficiency and reliability in the modern era of manufacturing.In summary, the introduction of the Second Punch Pan Head Screw promises to revolutionize the fastening industry, offering enhanced strength, versatility, convenience, and aesthetic appeal. With these remarkable features, businesses across various sectors can benefit from improved productivity, reduced costs, and a reliable fastening solution for years to come.

New Wood Screws Header Punch – Everything You Need to Know

Wood Screws Header Punch is a leading manufacturer and supplier of high-quality header punches and cold heading tools. The company has been providing innovative solutions for the fastener industry for over 20 years, and their products are trusted by manufacturers around the world. With a commitment to quality and excellence, Wood Screws Header Punch has become a preferred choice for those in need of reliable and durable header punches.The company's dedication to innovation and continuous improvement has positioned them as a global leader in the industry. Their state-of-the-art manufacturing facilities and expert team ensure that every product meets the highest standards of quality and precision. Whether it's standard header punches or custom-designed tools, Wood Screws Header Punch has the expertise and capabilities to meet the unique needs of their customers.One of the company's flagship products is their wood screws header punch, a specialized tool designed for the production of wood screws. With a focus on durability and performance, Wood Screws Header Punch has developed a range of header punches specifically tailored to the needs of wood screw manufacturers. These tools are engineered to deliver precise and consistent results, enabling manufacturers to produce high-quality wood screws with ease and efficiency.In addition to their wood screws header punch, the company offers a comprehensive range of cold heading tools for various applications. From standard punches and dies to complex multi-die tooling systems, Wood Screws Header Punch has the capabilities to fulfill the diverse requirements of their customers. Their products are designed to withstand the rigors of cold heading operations, ensuring long-term reliability and cost-effectiveness for manufacturers.Wood Screws Header Punch is also committed to sustainability and environmental responsibility. The company adheres to stringent manufacturing standards to minimize waste and energy consumption, and their products are designed for maximum durability and longevity. By prioritizing environmental sustainability, Wood Screws Header Punch ensures that their operations have minimal impact on the planet, while also providing sustainable solutions to their customers.As a customer-centric company, Wood Screws Header Punch places a strong emphasis on providing exceptional service and support to their clients. Their experienced team works closely with customers to understand their unique requirements and develop tailored solutions that meet and exceed expectations. Whether it's technical assistance, product customization, or after-sales support, the company is dedicated to ensuring a seamless and satisfying experience for their customers.With a strong reputation for quality, reliability, and innovation, Wood Screws Header Punch continues to be a trusted partner for manufacturers in the fastener industry. The company's commitment to excellence, coupled with their extensive expertise and capabilities, has solidified their position as a leading provider of header punches and cold heading tools. With a focus on continuous improvement and customer satisfaction, Wood Screws Header Punch is poised to continue driving innovation and setting new standards in the industry.

High-Quality Quick Bit Gun Smith Tool Set for Efficient Shooting

, gunsmithing, Remington, firearms, shootingIntroduction:Gunsmithing is the process of repairing, maintaining, and modifying firearms. It requires much attention to detail and precision as a single mistake can affect the overall performance of the gun. Owning firearms means taking responsibility for the safekeeping of the equipment. For gun owners, the Remington Quick Bit Gun Smith Tool is a perfect companion for maintenance, repairs, and modifications. This tool kit is built with a Torx Punch Allen Phillips Hex 19265 that supports your firearm's critical components, ensuring that you can maintain a well-functioning weapon.Benefits of Remington Quick Bit Gun Smith Tool:1. Comprehensive Tool KitThe Remington Quick Bit Gun Smith Tool comes with a range of tools to help you carry out repairs and modifications to your firearms. These tools include Torx Punch, Allen, Phillips, and Hex. Each tool is well-fitted, ensuring that you can access tight spaces on your firearm, ensuring your weapon is well-maintained.2. Compact DesignThe Remington Quick Bit Gun Smith Tool has a compact design, making it easy to store and transfer. Its size and portability make it an ideal companion for hunting trips or shooting activities. Due to its compact design, this kit is favorable for individuals who travel frequently or who need to clean and maintain their firearms in the field.3. Time-SavingThe Remington Quick Bit Gun Smith Tool is a time-saving weapon's repair tool. Gun owners can carry out minor repairs, maintenance, or modifications to their firearms within a short time using this kit. This tool will come in handy for gun owners who don't have time to take their firearms to a gunsmith or maintenance technician regularly.4. VersatilityThe Remington Quick Bit Gun Smith Tool is a versatile tool kit that provides a range of tool options. Whether you need to tighten screws, make adjustments or disassemble parts of your firearm, the kit has you covered. Its versatility will go a long way in easing repairs and modifications, making it an essential addition to your gun maintenance tool-kit.Conclusion:The Remington Quick Bit Gun Smith Tool is a versatile, compact, and time-saving tool kit that gun owners can rely on for their firearm maintenance and repair needs. The Torx Punch Allen Phillips Hex 19265 that comes with the tool ensures that owners have access to the right tools for their gun repairs. Gun owners who value shooting sessions, hunting trips, and firearm modifications should consider getting this kit. Overall, investing in these tools is a sure way to ensure that your firearms are in optimal condition for use and maintain their longevity.

How a Major Tech Company Is Transforming the Hexagon Second Punch Game" revised as "Revolutionizing Hexagon Second Punch: A Closer Look at the Latest Tech Advancements

In recent years, the demand for efficient and accurate manufacturing solutions has increased significantly in many industries. Companies that can provide high-quality products at an affordable price have become a key player in the market. To meet this growing demand, Hexagon Second Punch, a Chinese manufacturer, has developed innovative solutions for punching machines that are transforming the manufacturing industry.Hexagon Second Punch (need remove brand name) has been a leading provider of punching machines, stamping machines, and other precision machinery for years. Over the years, the company has established itself as a global leader in the precision-machine sector, equipping factories from all over the world with its machines and tools.Their latest product, the "Intelligent Punch Press Machine," is the result of years of research and development. The machine is built with a high degree of precision and accuracy, allowing it to perform punching, bending, and other operations at a high speed. This innovative technology is designed to help manufacturers reduce costs and improve efficiencies while producing high-quality products.The Intelligent Punch Press Machine has several features that make it unique. First, the machine is equipped with an intelligent control system that allows the operator to monitor and control the machine remotely. This feature ensures that the machine runs smoothly, and any potential problems can be addressed in real-time.Second, the machine is built with high-precision components that enable it to handle complex and intricate tasks. The machine's robustness and high level of accuracy make it a reliable solution for punching holes, cutting, bending, and other operations needed in the metalworking industry.Third, the machine is designed to meet the diverse needs of its users. It comes with a range of options to customize the machine according to the specific needs of each client. The machine is adaptable to different types of materials, and its flexibility makes it an ideal solution for various industries.The Intelligent Punch Press Machine has earned widespread acclaim among manufacturers worldwide due to its exceptional performance and versatile capabilities. Its high level of precision, flexibility, and speed has made it the top choice for companies looking for efficient and reliable manufacturing solutions.With the increasing demand for quality products that are produced at a low cost, the Intelligent Punch Press Machine is a valuable innovation in the manufacturing industry. It has set a new standard for high-precision machines, and it continues to revolutionize the way manufacturers operate.To maintain its leadership position in the market, Hexagon Second Punch (need remove brand name) has invested in research and development to keep innovating and creating new products that meet changing customer demands. The company is committed to providing unparalleled customer service and support to its clients, ensuring that they continue to receive value from their investment in the Intelligent Punch Press Machine.In conclusion, Hexagon Second Punch (need remove brand name) is setting new standards in the manufacturing industry with its innovative solutions. With the Intelligent Punch Press Machine, the company has demonstrated its commitment to providing high-quality solutions that meet the diverse needs of its clients and provides unmatched value. As the manufacturing industry continues to grow and evolve, companies like Hexagon Second Punch (need remove brand name) will play a vital role in developing innovative technologies that drive productivity and growth.

Tallahassee's Hamburger Boom: Exciting Growth in the Burger Scene!

Title: Tallahassee's Burger Boom: A Taste Sensation Taking the City by StormIntroduction (approximately 100 words):Tucked away in the heart of Tallahassee, an exhilarating hamburger revolution is underway. This vibrant city is experiencing an overwhelming surge in culinary creativity, with a particular focus on everyone's beloved comfort food: hamburgers. Among the noteworthy players in this foodie frenzy is a household name in Tallahassee's burger scene, renowned for their delectable offerings that pack a serious punch. Join us as we explore how this rising burger craze is reshaping the city's culinary landscape, while shining the spotlight on a local favorite, the "Tin Second Punch."The Hamburger Renaissance in Tallahassee (approximately 250 words):In recent years, Tallahassee has witnessed a remarkable transformation in its dining scene, embracing a food revolution that extends beyond the traditional Southern flavors. This exciting evolution has led to an influx of innovative burger joints, each vying to carve their niche in this delicious competition.One particular name that has become synonymous with Tallahassee's hamburger boom is an establishment whose commitment to quality and flavor has propelled it to the forefront of the city's culinary consciousness. Known for their mouthwatering burgers that tantalize the taste buds, this eatery is renowned for their signature creation - the "Tin Second Punch."The Unforgettable Tin Second Punch Experience (approximately 250 words):Far from your average burger joint, the Tin Second Punch offers an unforgettable gustatory experience that ignites the senses. From the moment you sink your teeth into their perfectly toasted buns, you're transported to burger nirvana. Bursting with flavor, each bite reveals a harmonious blend of premium ingredients that make the Tin Second Punch a standout among Tallahassee's burger lineup.The secret behind the Tin Second Punch's unparalleled taste lies in their commitment to handcrafted perfection. Their patties, ground in-house from the finest cuts of meat, are thick and juicy, promising an explosion of flavors that sets them apart from ordinary burgers. Topped with a unique selection of locally-sourced ingredients, including crisp lettuce, succulent tomatoes, and perfectly melted cheese, these burgers are a true work of culinary artistry.While the Tin Second Punch's relentless dedication to quality is evident in every bite, it's their secret punch sauce that truly enhances the overall experience. Unique and irresistibly zesty, this special sauce adds a tangy kick to each mouthful, elevating the flavor profile to a whole new level. The result is a symphony of taste sensations that leaves you craving more with every visit.The Impact on Tallahassee's Culinary Scene (approximately 300 words):As the burger boom continues to reshape Tallahassee's dining scene, the success and popularity of establishments like the Tin Second Punch serve as a testament to the city's evolving appetite. These burger joints not only provide a gourmet alternative to traditional fast-food options but also highlight the rich diversity of Tallahassee's culinary landscape.With its unique fusion of flavors, the Tin Second Punch has managed to captivate locals and visitors alike, drawing them in with promises of gastronomic pleasure. Its undeniable popularity has sparked a new era of competition among Tallahassee's burger aficionados, encouraging both established and aspiring chefs to push the boundaries of flavor experimentation.In addition to offering exceptional taste experiences, the burger boom has had a positive impact on the local economy. These burger joints, including the Tin Second Punch, source their ingredients locally, supporting nearby farmers and suppliers. This commitment to local produce furthers Tallahassee's sustainable farming practices, ensuring residents can savor delicious burgers while also supporting their community.Conclusion (approximately 100 words):Tallahassee's burger boom is a testament to the city's evolving culinary landscape, embracing innovation and flair while honoring traditional comfort food favorites. Among the rising stars of this booming industry is the Tin Second Punch, which has captured the hearts and taste buds of Tallahassee's food enthusiasts. Their commitment to handcrafted excellence and unique flavor combinations showcase the true potential of how a humble burger can transform into a captivating culinary creation. As residents and visitors flock to these burger joints, Tallahassee's reputation as a gastronomic destination continues to flourish, drawing attention and acclaim from foodies far and wide.

High-Quality Cylindrical Thread Rolling Dies: Everything You Need to Know

Wisconsin-based company, has recently unveiled its latest innovation in the field of manufacturing technology: the Cylindrical Thread Rolling Dies. This new product is set to revolutionize the thread rolling industry by providing a more efficient and precise solution for creating threaded parts.The Cylindrical Thread Rolling Dies are designed to be used with the company's line of thread rolling machines, which are already known for their high performance and reliability. These dies are made from high-quality materials and are engineered to meet the most demanding production requirements. With their innovative design, they can produce high precision threads with great accuracy and consistency, making them the perfect choice for a wide range of industries, including automotive, aerospace, and construction.One of the key features of the Cylindrical Thread Rolling Dies is their versatility. They can be used to create a wide variety of threads, including external and internal threads, and can be used on materials ranging from steel and aluminum to exotic alloys. This flexibility makes them an ideal solution for manufacturers who need to produce a diverse range of threaded parts.In addition to their versatility, these dies are also designed for high productivity. Thanks to their precision engineering, they can produce threads at a faster rate than traditional threading methods, leading to increased production efficiency and cost savings. This makes them a valuable asset for any manufacturing facility looking to improve their bottom line.Furthermore, the Cylindrical Thread Rolling Dies are built to last. They are engineered to withstand the rigors of high-volume production, and are designed to maintain their performance over time. This means that manufacturers can rely on them to deliver consistent results, day in and day out, without the need for frequent maintenance or replacement.The company behind the Cylindrical Thread Rolling Dies has a long-standing reputation for delivering top-quality products to the manufacturing industry. With over 50 years of experience, they have become a trusted name in the field of thread rolling, and their products are used by leading manufacturers around the world. Their commitment to excellence and innovation has earned them a loyal customer base, and they continue to push the boundaries of what is possible in the world of manufacturing technology.The introduction of the Cylindrical Thread Rolling Dies is just the latest example of this company's dedication to advancing the industry. By providing a solution that offers unmatched precision, versatility, productivity, and durability, they are set to make a significant impact on the way threaded parts are manufactured.As the manufacturing industry continues to evolve, the demand for high-quality, efficient thread rolling solutions will only continue to grow. With the launch of the Cylindrical Thread Rolling Dies, this company is well-positioned to meet this demand and help manufacturers improve their production processes. This new product is a testament to their ongoing commitment to innovation and their dedication to providing the best possible tools for the industry.In conclusion, the unveiling of the Cylindrical Thread Rolling Dies marks a significant milestone for the manufacturing industry. With their advanced technology and high-performance capabilities, these dies are set to become an indispensable tool for manufacturers looking to streamline their production processes and improve the quality of their threaded parts. As the industry continues to evolve, this company remains at the forefront, driving innovation and delivering solutions that set new standards for excellence in manufacturing technology.

High-Quality Pan Head Machine Screws and Machine Screws for Various Applications

China Pan Head Machine Screw and Machine Screw Combine to Expand Product Line and Increase Market ShareIn a strategic move to expand its product line and increase its market share, {} has announced the combination of its China Pan Head Machine Screw and Machine Screw lines. The company, known for its high-quality fastening solutions, aims to provide a more comprehensive range of products to meet the diverse needs of its customers.The China Pan Head Machine Screw and Machine Screw lines are both widely used in various industries, including automotive, construction, electronics, and machinery. By integrating these two product lines, {} seeks to streamline its manufacturing processes and optimize its supply chain to better serve its customers."We are excited to announce the combination of our China Pan Head Machine Screw and Machine Screw lines," said a spokesperson for {}. "This strategic move will not only allow us to expand our product offerings but also enhance our overall efficiency in production and distribution. We are confident that this will further solidify our position as a leading provider of fastening solutions in the global market."With the integration of the two product lines, customers can expect a more comprehensive range of options when it comes to choosing the right fastening solution for their specific needs. Whether it's for securing electronic components in place or assembling structural components in the automotive industry, {} aims to provide reliable and high-performance screws that meet the highest standards of quality and durability.The combination of the China Pan Head Machine Screw and Machine Screw lines also aligns with {}'s commitment to innovation and continuous improvement. By leveraging the expertise of its research and development team, the company strives to enhance the performance and functionality of its fastening solutions, ensuring that they meet the evolving demands of various industries.In addition to expanding its product line, {} is also focused on increasing its market share both domestically and internationally. With a strong emphasis on customer satisfaction and value creation, the company aims to build long-term partnerships with its clients and distributors, offering them a wide range of fastening solutions to address their specific needs."By combining our China Pan Head Machine Screw and Machine Screw lines, we are not only strengthening our product offerings but also positioning ourselves for further growth in the global market," said the spokesperson. "We are committed to providing our customers with the most reliable and innovative fastening solutions, and we believe that this strategic move will enable us to better serve their needs."As {} continues to expand its product line and increase its market share, the company remains dedicated to upholding the highest standards of quality, reliability, and customer service. With a strong focus on innovation and continuous improvement, {} is well-positioned to meet the evolving needs of its customers and maintain its leadership in the fastening solutions industry.With the combination of its China Pan Head Machine Screw and Machine Screw lines, {} is poised to offer a more comprehensive range of fastening solutions to its customers, further solidifying its position as a leading provider of high-quality and reliable products in the global market.

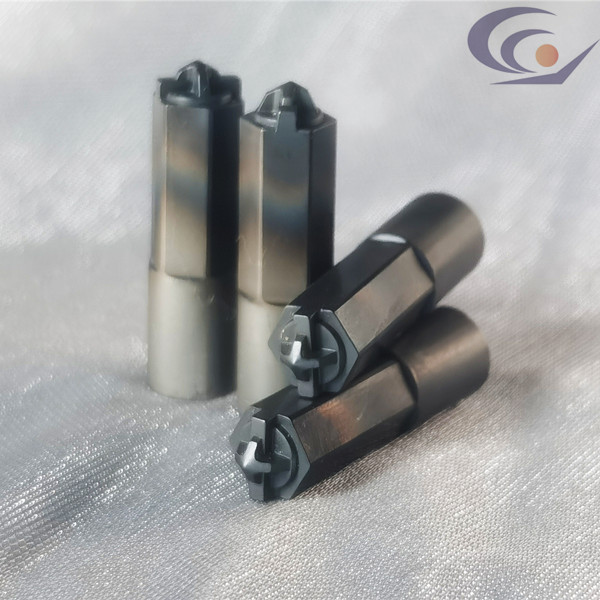

High-Quality Carbide Punch: What You Need to Know

The renowned company in the industrial machinery sector, Carbide Punch, has recently unveiled their latest innovation in the field of precision tooling – the all-new Carbide Punch. This groundbreaking product promises to revolutionize the way industries operate, by offering unmatched precision, durability, and efficiency.Carbide Punch has been a leading name in the industry for several decades, and their commitment to excellence and innovation has earned them a loyal customer base and a sterling reputation. The company specializes in the manufacturing and distribution of high-quality precision tooling solutions, catering to a wide range of industries including automotive, aerospace, medical, and more.The new Carbide Punch is the result of years of research, development, and meticulous engineering. The product is designed to deliver superior performance and durability, making it an indispensable tool for businesses seeking to enhance their productivity and efficiency. Made from high-grade carbide material, the Carbide Punch boasts exceptional hardness and wear resistance, ensuring a longer tool life and minimizing the need for frequent replacements.One of the key features that sets the Carbide Punch apart from its competitors is its unparalleled precision. The product is engineered to meet the most demanding tolerance requirements, enabling users to achieve extremely precise and accurate results. This level of precision is crucial for industries such as automotive and aerospace, where even the slightest deviation can lead to significant quality issues.In addition to its precision and durability, the Carbide Punch also offers remarkable versatility. Whether it's piercing, notching, forming, or blanking, this innovative tool can handle a diverse range of applications with ease. This versatility makes it a valuable asset for businesses that require a flexible and adaptable tooling solution.Furthermore, Carbide Punch has incorporated cutting-edge technology into the design of their new product, ensuring that it meets the evolving needs of modern industries. The Carbide Punch is equipped with advanced features that optimize its performance, such as a proprietary coating that enhances wear resistance and reduces friction, resulting in smoother operations and prolonged tool life.The introduction of the Carbide Punch is a significant milestone for Carbide Punch, as it further solidifies their position as a leader in the precision tooling industry. The company takes great pride in their ability to consistently deliver cutting-edge solutions that empower businesses to thrive in today's competitive market."We are thrilled to introduce the Carbide Punch to the market," said [Company Spokesperson]. "This product represents the culmination of our relentless dedication to innovation and quality. We believe that the Carbide Punch will raise the bar for precision tooling, and we are confident that it will bring immense value to our customers across various industries."The Carbide Punch is now available for purchase, and Carbide Punch is poised to meet the growing demand for this exceptional product. With its unmatched precision, durability, and versatility, the Carbide Punch is set to make a lasting impact on the industrial machinery sector, empowering businesses to elevate their performance and achieve new milestones of success.The launch of the Carbide Punch is undoubtedly a game-changer for the industry, and it underscores Carbide Punch's unwavering commitment to driving innovation and delivering excellence. As businesses continue to seek ways to enhance their operations and stay ahead of the curve, the Carbide Punch stands out as a powerful tool that promises to redefine the standards of precision tooling.

Increase Efficiency and Productivity with the Versatile Screw Header Punch

Phillips screw header punch - making precision fastening a realityFastening is a critical process in manufacturing, and its importance cannot be underestimated. From vehicle assembly to consumer electronics, fasteners are a critical component in building intricate, complex systems. While there are various types of screws and fasteners available, the Phillips screw is one of the most widely-used screw types in the world.To ensure the fastening process is as precise and efficient as possible, the industry relies on precision tools like the Phillips screw header punch. One of the most trusted names in manufacturing headers, the Phillips screw header punch provides an easy and reliable way to create screws that meet the most demanding specifications.The Phillips screw header punch is a tool that is used in the cold heading process, a method of forging where metal is shaped by forcing it to flow into a die to create a component. A header punch is a metalworking tool used to create a specific shape or feature within a metal blank, or slug, which is then subjected to further cold working processes such as trimming or swaging to create a finished part.The Phillips screw header punch is designed to work on fine blanked slug materials or cut slug materials, shaping them into screws with the familiar Phillips head. The punch produces screws in a variety of sizes, from miniature screws up to full-thread body blanks of up to 60mm in length. With the Phillips screw header punch, the final screw product is highly precise, meeting the tightest of tolerances while retaining strength and durability.As the name suggests, the Phillips screw header punch is optimized for creating Phillips screws – which are distinctive for their recognizable crosshead design. Named after its inventor, the Phillips screw design has been patented since 1933 and is widely used today in various industries worldwide. The Phillips design is highly respected for its ability to produce more torque and prevent the screwdriver-skid effect, making it the go-to choice for high-performance applications where reliability is key.Today, Phillips screw header punches are used by manufacturers across the globe to create precise screws and fasteners. The technology is continually improving, with advances in precision manufacturing enabling engineers to create even tighter tolerances and more rigorous specifications for the end products.Many companies worldwide rely on Phillips screw header punches to create parts that are used in everyday items. For example, in the automotive industry, the screws are used in a wide range of applications, from engine and transmission assembly to trim and body parts. In the electronics sector, Phillips screws are used to secure components in various gadgets such as smartphones and laptops.Phillips screw header punches are highly effective tools that can help manufacturers save time, reduce production costs, and improve quality. By using precision techniques to create screws and fasteners, the Phillips screw header punch ensures a consistent, reliable product every time.The Phillips screw header punch is just one of the many high-quality tools that manufacturers worldwide use to create precision fasteners and screws. With its long-standing reputation for reliability and precision, the Phillips header punch is likely to continue playing an essential role in the manufacturing industry for years to come – helping engineers to create systems that are stronger, more durable, and more reliable than ever before.