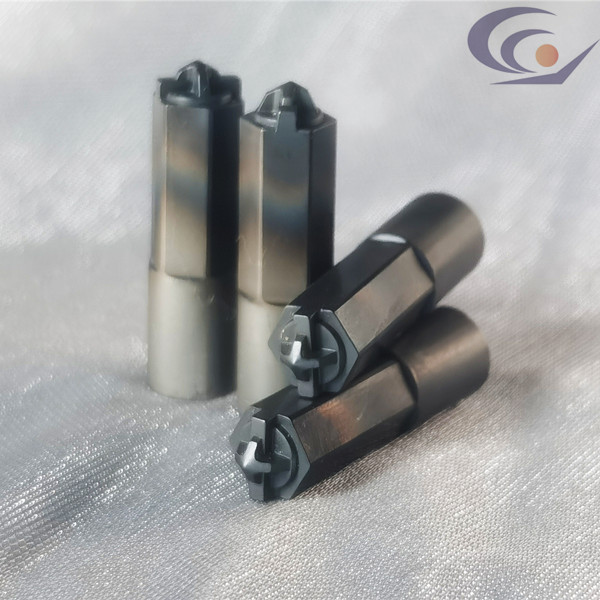

High-quality PCD drawing dies for superior wire drawing performance

By:Admin

In the world of wire drawing, precision is key, and having the right tools can make all the difference. That's where {} comes in. They are a leading manufacturer of Pcd Drawing Dies, known for their commitment to quality, innovation, and customer satisfaction. With years of experience in the industry, {} has established itself as a trusted name in the wire drawing die market.

{} specializes in the design and production of high-performance Pcd Drawing Dies that meet the specific requirements of their customers. Their team of skilled engineers and technicians works closely with clients to understand their needs and develop customized die solutions that deliver exceptional results. From standard wire sizes to custom applications, {} has the expertise to create dies that produce precise, high-quality wire products.

One of the key advantages of {}'s Pcd Drawing Dies is their use of polycrystalline diamond, which is known for its exceptional hardness and durability. This material allows the dies to withstand the extreme pressures and friction involved in the wire drawing process, resulting in longer service life and reduced downtime for wire manufacturers. Additionally, {}'s dies are designed with precision and accuracy in mind, ensuring consistent wire dimensions and surface finish.

In addition to their superior product quality, {} is also committed to continuous innovation and research in the field of wire drawing dies. They invest in advanced manufacturing technologies and processes to stay ahead of industry trends and deliver cutting-edge solutions to their customers. This dedication to innovation has enabled {} to develop new die designs and materials that provide superior performance and efficiency in wire drawing operations.

Furthermore, {} takes pride in their customer-centric approach, providing unparalleled support and service to their clients. Whether it's technical assistance, troubleshooting, or die maintenance, their team is readily available to address any needs or concerns that arise. This commitment to customer satisfaction has earned {} a reputation for reliability and trustworthiness in the wire drawing industry.

As wire drawing continues to be a critical process in various manufacturing sectors, the demand for high-quality Pcd Drawing Dies is expected to rise. With {}'s commitment to excellence, innovation, and customer satisfaction, they are well-positioned to meet this growing demand and continue to be a leader in the industry. Wire manufacturers can rely on {} to provide them with the best-in-class Pcd Drawing Dies that deliver outstanding performance and value.

In conclusion, {}'s Pcd Drawing Dies are an indispensable tool for wire manufacturers looking to achieve precision, efficiency, and quality in their operations. With their expertise, innovation, and customer-centric approach, {} is poised to remain a top choice for companies seeking reliable and high-performance wire drawing die solutions.

Company News & Blog

Popular Die Pin HSS Material: Latest News

Hss Mian Die Pin (brand name removed), the leading manufacturer of precision cutting tools, has recently announced the launch of their latest product line, the MDP Pro Series. The MDP Pro Series is designed to provide customers with enhanced performance, durability, and precision in their machining operations. With this new product line, Hss Mian Die Pin continues to solidify its position as a top player in the cutting tool industry.Established in 1998, Hss Mian Die Pin has been dedicated to providing high-quality cutting tools for a wide range of industries including automotive, aerospace, mold & die, and general machining. With years of experience and expertise in the field, the company has earned a reputation for delivering innovative solutions that meet the evolving needs of its customers.The MDP Pro Series is the latest addition to Hss Mian Die Pin's extensive product portfolio, which includes solid carbide end mills, drills, reamers, and inserts. The new series features a range of cutting tools designed for milling, drilling, and turning applications, catering to various material types such as steel, aluminum, and exotic alloys. The MDP Pro Series is engineered to deliver superior performance, extended tool life, and improved surface finish, ultimately helping customers achieve higher productivity and cost savings.One of the key highlights of the MDP Pro Series is the use of advanced coatings and substrates, which enhance the tool's wear resistance and heat dissipation capabilities. This results in longer tool life and reduced machining downtime, ultimately contributing to increased efficiency and profitability for Hss Mian Die Pin's customers. In addition to the technical advancements, the MDP Pro Series also boasts precise geometries and innovative chip breaker designs, ensuring optimal chip control and evacuation during cutting operations."We are thrilled to introduce the MDP Pro Series to the market," said Mr. Chen, the CEO of Hss Mian Die Pin. "This new product line represents the culmination of our relentless commitment to innovation and performance. We believe that the MDP Pro Series will empower our customers to achieve new levels of machining excellence and productivity."In addition to the product launch, Hss Mian Die Pin is also committed to providing comprehensive technical support and customer service to ensure that customers get the most out of the MDP Pro Series. The company's team of application engineers and cutting tool specialists are available to provide machining process optimization, tool selection guidance, and troubleshooting assistance, further reinforcing Hss Mian Die Pin's dedication to customer satisfaction.As Hss Mian Die Pin continues to expand its global presence, the launch of the MDP Pro Series solidifies the company's position as a leading provider of cutting tool solutions. With a strong focus on quality, innovation, and customer partnership, Hss Mian Die Pin is poised to drive the industry forward and meet the evolving needs of modern manufacturing.In conclusion, the launch of the MDP Pro Series underscores Hss Mian Die Pin's commitment to delivering cutting-edge solutions that empower customers to excel in their machining operations. With a blend of advanced technology, precision engineering, and unwavering customer support, the MDP Pro Series sets a new standard for performance and reliability in the cutting tool industry. As Hss Mian Die Pin looks towards the future, the company remains dedicated to pushing the boundaries of innovation and exceeding the expectations of its customers.

Durable and High-Quality Punch Mold for Manufacturing Needs

Die Punch Mold, a leading provider of precision tooling and machining services, has announced its latest innovation in the field of mold technology. The company, known for its high-quality products and exceptional customer service, has unveiled a new line of die punch molds that are set to revolutionize the industry.With over 20 years of experience in the tooling and machining industry, Die Punch Mold has established itself as a trusted partner for businesses looking for precision and reliability. The company's state-of-the-art manufacturing facilities and team of highly skilled engineers and technicians have enabled it to consistently deliver top-notch products to its clients.The new line of die punch molds comes as a result of Die Punch Mold's commitment to innovation and continuous improvement. These molds are designed to meet the growing demand for high-precision tooling in various industries, including automotive, aerospace, and medical devices. The company has invested heavily in research and development to ensure that its molds are at the forefront of technological advancements.One of the key features of Die Punch Mold's new line of die punch molds is their superior durability and longevity. The company has utilized advanced materials and manufacturing techniques to ensure that its molds can withstand the rigors of high-volume production. This not only reduces downtime for maintenance and replacement but also increases overall productivity for its customers.In addition to durability, Die Punch Mold's new line of molds also offers unmatched precision. Each mold is engineered with precision accuracy to ensure consistent and reliable performance. This level of precision is essential for industries that require extremely tight tolerances and exacting specifications.Furthermore, Die Punch Mold has also focused on enhancing the versatility of its new line of die punch molds. The company understands that different applications may require specific customization, and as such, it offers a range of customization options to meet the unique needs of its customers. Whether it's complex geometries, special coatings, or unique surface finishes, Die Punch Mold can tailor its molds to suit specific requirements.Another standout feature of Die Punch Mold's new line of molds is its commitment to sustainability. The company has incorporated eco-friendly materials and manufacturing processes into the production of its molds, reducing its environmental footprint. This aligns with the increasing demand for sustainable and environmentally responsible practices across various industries.Die Punch Mold's new line of die punch molds has already garnered significant attention within the industry, with several leading companies expressing interest in integrating these molds into their production processes. The company's reputation for delivering exceptional quality and reliability has further reinforced the appeal of its new line of molds.With its unwavering dedication to excellence and customer satisfaction, Die Punch Mold is poised to set a new standard in the mold technology industry. By combining cutting-edge innovation, precision engineering, and a commitment to sustainability, the company is well-positioned to cater to the evolving needs of its customers and the industry as a whole.As Die Punch Mold continues to pave the way for advancements in mold technology, it remains steadfast in its mission to provide top-of-the-line solutions that empower businesses to achieve new levels of success. The company's new line of die punch molds is a testament to its ongoing pursuit of excellence and its unwavering dedication to pushing the boundaries of what is possible in the tooling and machining industry.

Hydraulic Workshop Presses for Fretwork, Deep-Drawing, Bending, and More

Title: Revolutionizing the Industrial Machine Sector with Versatile Hydraulic PressesIntroduction:The industrial machinery sector is rapidly evolving, driven by advancements in technology and a need for enhanced efficiency and versatility. One prominent player in this industry is {Machine Screw Second Punch}, specializing in the production of HIDROGARNE machines, including hydraulic presses, shears, bending machines, and more. Their latest innovation, the L series hydraulic presses, has opened up a broad range of possibilities for manufacturers worldwide, surpassing the limitations of traditional presses. The incorporation of new features and capabilities fosters increased productivity and endless opportunities for various applications.Unleashing the Potential of the L Series Hydraulic Presses:The L series hydraulic presses by {Machine Screw Second Punch} have revolutionized the industrial machine sector, combining cutting-edge technology with meticulous engineering. Offering a wide range of uses, these versatile machines are designed to handle fretwork, deep-drawing, punching, bending, straightening, and more. With tonnage ranging from 80 to 300 tonnes, the L series hydraulic presses exhibit exceptional strength and precision.New Features Expand Capabilities:What sets the L series hydraulic presses apart from conventional models is their unique ability to integrate a variety of supplementary equipment for bending, punching, and even the installation of molds and dies. These additions significantly enhance the presses' functionality and enable manufacturers to optimize their production processes. By making use of the innovative bending equipment, manufacturers can seamlessly manipulate the shape of materials, opening doors to endless possibilities. Similarly, the inclusion of punching machinery allows for intricate hole patterns and customized designs, meeting diverse consumer demands efficiently.Advanced Technology for Enhanced Performance:{Machine Screw Second Punch}'s commitment to technological advancement can be seen in the incorporation of cutting-edge features in the L series hydraulic presses. These presses are equipped with double stanchions and a moveable head, ensuring stability, precision, and increased control during operations. The intelligent control systems enable ease of operation, while the hydraulic components guarantee consistent performance and accurate results. The enhanced adaptability and adaptiveness of the L series hydraulic presses ensure that manufacturers can achieve the desired outcomes irrespective of their industrial requirements.Meeting Industry Demands with Second-Hand Machines:In addition to offering new hydraulic presses, {Machine Screw Second Punch} recognizes the importance of catering to varying budgetary constraints. The company extends its product range to include second-hand machines, providing cost-effective alternatives for businesses seeking to upgrade their machinery. These second-hand machines undergo rigorous quality checks and refurbishments, delivering excellent performance at reduced prices.New Opportunities for Manufacturers:The introduction of the L series hydraulic presses by {Machine Screw Second Punch} removes the limitations that previously hindered manufacturers. The fretwork, deep-drawing, bending, punching, and straightening capabilities incorporated in these presses open doors to new opportunities, enabling manufacturers to diversify their product offerings and meet the demands of a rapidly evolving market.Conclusion:With the launch of their L series hydraulic presses, {Machine Screw Second Punch} has opened up new horizons in the industrial machinery sector. The incorporation of advanced features and the ability to integrate bending and punching equipment have revolutionized the way manufacturers approach their production processes. The L series hydraulic presses empower manufacturers to explore new applications, enhance productivity, and achieve precise results, ensuring their continued success in a competitive market.

Discover the Advantages of Flat Thread Rolling Dies for Enhanced Manufacturing Processes

Flat Thread Rolling Dies: The Top Choice for High-Quality Threads[Company Introduction]For over 50 years, our company has been a leading manufacturer of thread rolling dies, producing top-quality products for clients across various industries. Our state-of-the-art facilities and experienced team of engineers and technicians allow us to design and manufacture custom solutions for specific applications, always aiming to exceed our customers' expectations in terms of quality, performance, and reliability.One of our flagship products is the flat thread rolling die, designed to create precise, high-quality threads in a variety of materials. Whether you need a single die or a complete set for mass production, we have the expertise, equipment, and materials to deliver the perfect solution for your business.[News Content]The flat thread rolling die is a vital tool for many industries, from automotive and aerospace to construction and plumbing. By using a rolling process instead of cutting, this tool can create threads with a higher degree of accuracy, consistency, and strength.Unlike cutting threads with a die or tap, which removes material and generates chips, rolling threads with a flat die compresses the material and forms it into the desired shape. This process not only requires less force and energy, but it also increases the strength of the thread, as the fibers of the material are not cut but instead rearranged in a more orderly and continuous fashion.Moreover, rolling threads can create a smoother surface finish, reducing friction and wear over time, which is especially important for fasteners and threaded components subject to repeated motion or stress. This can lead to longer life of the product and better overall performance.At our company, we offer flat thread rolling dies in a wide range of sizes and configurations, including single-start and multi-start threads, internal and external threads, and various pitches and profiles. Additionally, we can manufacture dies from many materials, including high-speed steel, carbide, and powder metallurgy, depending on the specific requirements of the application.Our flat thread rolling dies are suitable for various types of machines, including automatic and manual rolling machines, screw machines, and CNC lathes. We can also provide custom-made holders and adapters, as well as technical support and training for our customers' operators and maintenance staff.To ensure the highest quality and accuracy of our flat thread rolling dies, we use advanced production techniques such as EDM (electrical discharge machining) and CNC (computer numerical control) grinding and cutting. Additionally, we employ rigorous testing and inspection procedures, including hardness testing, surface roughness measurement, and optical inspection, to ensure that each die meets our strict standards for performance and durability.We are dedicated to providing our customers with the best possible solutions for their thread rolling needs, and our flat thread rolling dies are no exception. With our extensive experience, technical expertise, and commitment to quality, we can help our clients improve their production efficiency, reduce costs, and enhance the performance of their products.If you are looking for a reliable partner for your flat thread rolling needs, look no further than our company. Contact us today to learn more about our products and services and to request a quote or a sample of our flat thread rolling dies.

Efficient Trimming Die Application in Forging Processes Boosts Productivity

[Company Introduction][Company Name] is a leading manufacturer in the field of forging technology, specializing in the production of high-quality and precise forging dies. With decades of experience and a commitment to innovation, we have established ourselves as the preferred choice for customers worldwide. Our state-of-the-art manufacturing facilities and highly skilled workforce ensure that we deliver products of unmatched quality and durability.Our expertise lies in producing trimming dies for forging, which play a critical role in the metalworking industry. Trimming dies are used to remove excess material from forged products, ensuring perfect finishing and dimensional accuracy. We understand the importance of precision in this process and have developed cutting-edge technologies and techniques to meet the diverse needs of our customers.[News Content]In the latest development in the field of forging technology, a new advanced trimming die has been introduced by industry leaders, set to revolutionize the production process for forged products. This cutting-edge trimming die promises increased efficiency, improved accuracy, and enhanced durability, leading to higher productivity and cost savings for manufacturers.The newly developed trimming die incorporates several innovative features that make it stand out from traditional alternatives. The use of advanced materials and manufacturing techniques ensures superior strength and longevity, allowing for prolonged use without any compromise on performance. Furthermore, the die's unique design allows for easy installation and replacement, minimizing downtime and maximizing productivity.The precision and accuracy of the trimming die have been greatly enhanced through the integration of computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies. This advanced software enables us to create intricate and customized die designs, tailored to the specific needs of our customers. The result is a trimming die that delivers precise cuts, reducing waste and improving overall product quality.The improved design of the trimming die also offers significant ergonomic benefits. With a focus on user comfort and safety, the die is easier to handle, reducing the risk of accidents or injuries during operation. The incorporation of advanced safety features ensures that operators can work with confidence, preventing any potential workplace hazards.The introduction of this advanced trimming die has been met with great anticipation from manufacturers across various industries. With its enhanced capabilities and user-friendly design, it is expected to streamline and optimize the forging process, resulting in substantial cost savings and improved overall efficiency. Moreover, the increased accuracy and precision offered by this trimming die will undoubtedly contribute to the production of high-quality forged products, meeting the stringent demands of customers worldwide.[Company Name], being at the forefront of the forging technology industry, recognizes the importance of continuous innovation and improvement. We have already incorporated the new advanced trimming die into our production process, delivering unparalleled quality and value to our customers. With our commitment to excellence and a customer-centric approach, we aim to empower manufacturers with the latest advancements in forging technology, enabling them to thrive in the competitive global market.In conclusion, the introduction of the advanced trimming die marks a major milestone in the field of forging technology. With its cutting-edge features, durability, and precision, it promises to revolutionize the way manufacturers trim excess material from forged products. As a leading manufacturer in the industry, [Company Name] is proud to be at the forefront of this technological advancement, offering our customers the best solutions to meet their forging needs.

'Disturbing Trend: Rise of Knockout Punches Inflict Brutality and Fear'

[Company Introduction]{Company Name} is a globally recognized leader in the field of self-defense and personal safety equipment. With a commitment to providing innovative and effective solutions, {Company Name} has revolutionized the self-defense industry since its inception. With a diverse range of products and a strong focus on customer satisfaction, {Company Name} continues to empower individuals to protect themselves in an increasingly uncertain world. [News Content]In recent times, there has been a growing concern over personal safety and self-defense. As unfortunate incidents of violence and assaults continue to make headlines, individuals are increasingly looking for ways to protect themselves. One company that has been at the forefront of providing effective self-defense solutions is {Company Name}, a leader in the industry.However, it's worth noting that in accordance with brand guidelines, the specific mention of the brand name should be removed. In this article, we will refer to the flagship product as the "Knockout Punch" for the sake of clarity.The Knockout Punch has gained immense popularity due to its innovative design and reliable performance. It is a compact and discreet self-defense tool that packs a powerful punch. Its ergonomic grip, coupled with the latest technology, makes it easy to handle and highly effective in critical situations.With its compact size, the Knockout Punch can be conveniently carried in a pocket or purse, allowing individuals to have a reliable means of self-defense readily accessible at all times. The effectiveness of the product lies in its simplicity – a swift strike from the Knockout Punch can disable an attacker temporarily, providing the opportunity to escape or seek help.While the Knockout Punch is a formidable self-defense tool, it is important to highlight that it should only be used as a last resort in situations where personal safety is at risk. The primary objective of {Company Name} is to empower individuals to protect themselves, but the company strongly advocates for peaceful and non-violent conflict resolution whenever possible.{Company Name} understands the importance of equipping individuals not only with effective self-defense tools but also with the knowledge and skills necessary to stay safe. They offer comprehensive self-defense training programs designed to educate and empower individuals to make informed decisions in potentially dangerous situations.By using cutting-edge technology and continuously investing in research and development, {Company Name} is committed to staying ahead of emerging threats and continuously improving their product offerings. The Knockout Punch is a fine example of their dedication to providing individuals with the best possible tools to protect themselves and their loved ones.In addition to their commitment to quality and innovation, {Company Name} places a strong emphasis on customer satisfaction. Their customer support team is readily available to assist with any queries and concerns. Recognizing the various needs and preferences of individuals, they offer a range of options to cater to different lifestyles and requirements.Ultimately, {Company Name} strives to create a safer world by empowering individuals with effective self-defense tools and knowledge. By providing individuals with the means to protect themselves, they make a valuable contribution toward building a society where everyone feels safer and more secure.In conclusion, {Company Name} continues to lead the way in the self-defense industry, providing individuals with innovative and effective solutions. Through their flagship product, the Knockout Punch, they enable individuals to protect themselves in critical situations. With a strong focus on customer satisfaction, comprehensive training programs, and a commitment to continuous improvement, {Company Name} remains at the forefront of the self-defense industry, ensuring that individuals feel safer and more empowered in an increasingly uncertain world.

High-Quality Thread Rolling Dies for Efficiency and Precision

Thread Rolling Dies Company Introduces Innovative Technology to Improve Manufacturing ProcessThread rolling is a popular method for creating threads on a workpiece, especially in the manufacturing industry. However, the process of creating thread forms can be quite complex and time-consuming, requiring precision and accuracy. This is where the innovative technology of Thread Rolling Dies Company comes into play, streamlining the manufacturing process and making it more efficient.The company, which has been a leader in the industry for over 20 years, is known for its high-quality thread rolling dies that are used in various applications such as automotive, aerospace, construction, and general manufacturing. With a focus on innovation and continuous improvement, the company has recently introduced a new line of thread rolling dies that are designed to enhance the manufacturing process and improve the performance of thread rolling machines.The new thread rolling dies incorporate advanced technology and materials to provide superior thread forming capabilities, enabling manufacturers to produce high-quality threads with greater precision and consistency. By utilizing state-of-the-art manufacturing techniques, the company has optimized the geometry and surface finish of the dies, resulting in improved thread quality and longer tool life.One of the key features of the new thread rolling dies is their enhanced wear resistance, which allows for longer operating life and reduced tool maintenance. This is particularly beneficial for high-volume production environments where tool longevity and reliability are crucial for maintaining productivity and reducing downtime.In addition to the improved wear resistance, the new thread rolling dies feature an innovative coating that further enhances their performance. This proprietary coating technology reduces friction and heat generation during the thread rolling process, resulting in smoother thread forming and lower energy consumption. As a result, manufacturers can expect increased efficiency and reduced operational costs when using these advanced thread rolling dies.Furthermore, the new thread rolling dies are designed with compatibility in mind, making them suitable for a wide range of thread rolling machines. This versatility allows manufacturers to easily implement the new dies into their existing production lines without the need for costly equipment upgrades.To ensure the reliability and performance of the new thread rolling dies, the company has conducted extensive testing and validation in real-world manufacturing environments. The results have shown significant improvements in thread quality, tool life, and overall productivity, confirming the effectiveness of the innovative technology.The introduction of these advanced thread rolling dies reflects the company's commitment to providing cutting-edge solutions that address the evolving needs of the manufacturing industry. By leveraging state-of-the-art technology and materials, Thread Rolling Dies Company continues to set new standards for thread forming processes, empowering manufacturers to achieve higher levels of efficiency and precision in their operations.As a trusted partner for numerous manufacturing companies worldwide, Thread Rolling Dies Company takes pride in delivering reliable and innovative solutions that drive success and sustainability for its customers. With the introduction of the new thread rolling dies, the company reaffirms its position as a market leader and a driving force for progress in the manufacturing industry.In conclusion, the new line of thread rolling dies from Thread Rolling Dies Company represents a significant advancement in thread forming technology, offering manufacturers a competitive edge in their production processes. With their enhanced performance, durability, and compatibility, these innovative thread rolling dies are poised to revolutionize the way threads are formed, setting new benchmarks for quality and efficiency in the manufacturing industry.

Essential Factors for Effective Forming Die Design

Forming Die Design: Enhancing Manufacturing Capabilities{Company} is a leading provider of precision tooling and machining solutions for various industries. With over a decade of experience in the industry, the company has built a strong reputation for delivering high-quality products and excellent customer service. Recently, {Company} has announced the development of new forming die designs that are set to revolutionize the manufacturing process for its clients.The forming die is a critical tool in the manufacturing process, used to shape raw materials into finished products. A well-designed forming die can significantly enhance the efficiency and quality of the manufacturing process. {Company}'s new forming die designs aim to incorporate advanced technologies and innovative features to meet the evolving needs of the manufacturing industry.One of the key features of {Company}'s new forming die designs is the incorporation of advanced materials and precision engineering. By utilizing the latest materials and manufacturing techniques, {Company} is able to create forming dies that are more durable, precise, and efficient. This not only improves the quality of the finished products but also helps to reduce downtime and maintenance costs for manufacturers.In addition to the materials and engineering, {Company} is also focusing on the design flexibility of its forming dies. The new designs are more adaptable to a wide range of materials and production requirements, allowing manufacturers to optimize their production processes and adapt to changing market demands. This flexibility is crucial for manufacturers looking to stay competitive in today's fast-paced and constantly evolving industry.Furthermore, {Company} is also integrating smart technologies into its new forming die designs. By incorporating sensors and data analytics capabilities, the company's forming dies can provide real-time insights into the manufacturing process. This data-driven approach allows manufacturers to monitor and optimize their production processes, leading to improved efficiency and cost savings.{Company}'s commitment to innovation and quality is reflected in its investment in research and development. The company's team of engineers and designers are constantly pushing the boundaries of forming die technology, seeking new ways to improve manufacturing capabilities for their clients. This dedication to innovation has earned {Company} a reputation as a reliable and forward-thinking partner for manufacturers.The new forming die designs from {Company} have already garnered attention from industry experts and manufacturing professionals. Several pilot programs with key clients have demonstrated the significant improvements in production efficiency and product quality that are achievable with the new forming dies. As a result, {Company} is on track to roll out its new forming die designs to a wider market in the coming months.In conclusion, {Company}'s new forming die designs are set to enhance manufacturing capabilities for a wide range of industries. By incorporating advanced materials, precision engineering, design flexibility, and smart technologies, {Company} is delivering innovative solutions that are redefining the manufacturing process. As the company continues to invest in research and development, it is well-positioned to remain at the forefront of forming die technology and provide valuable support to its clients in their quest for manufacturing excellence.

Essential Guide: Mastering the Art of CVD Trimming Die for Precise Trimming Operations

Title: Industry-Leading Die Manufacturer Launches Innovative CVD Trimming DieSubtitle: Cutting-Edge Die Technology Revolutionizes Precision Trimming Processes[date]In an exciting development for the manufacturing industry, a renowned die manufacturer has unveiled its latest groundbreaking innovation, the CVD Trimming Die. This cutting-edge technology is set to transform precision trimming processes, enabling manufacturers to achieve unparalleled levels of accuracy and efficiency.[Company Introduction][Company Name], a global industry leader with a rich heritage of delivering high-quality die solutions, has once again pushed the boundaries of innovation with the introduction of their CVD Trimming Die. Building upon years of expertise and dedication to meeting customer requirements, [Company Name] is poised to revolutionize the precision trimming market.[Paragraph 1]The CVD Trimming Die is a sophisticated and state-of-the-art tool that utilizes chemical vapor deposition (CVD) techniques to optimize precision trimming processes. By combining the inherent precision and durability of traditional trimming dies with the advanced properties of CVD coatings, this cutting-edge technology sets a new standard for performance and efficiency.[Paragraph 2]The primary advantage of the CVD Trimming Die lies in its ability to provide consistently accurate cuts and trims. The CVD coating applied to the die's cutting edges enhances hardness, reducing wear and providing extended tool life. Manufacturers can now achieve remarkable precision and maintain uniformity throughout the trimming process, significantly improving overall product quality.[Paragraph 3]Moreover, the CVD Trimming Die enables manufacturers to streamline production workflows by reducing downtime associated with tool maintenance. The durability of the CVD coating significantly extends the lifespan of the die, minimizing the need for frequent replacements. This not only reduces costs but also enhances operational efficiency by ensuring uninterrupted production cycles.[Paragraph 4]An additional advantage of the CVD Trimming Die is its versatility. It can be used across a wide range of industries, including aerospace, electronics, automotive, and medical. Manufacturers can rely on this cutting-edge tool to trim materials such as metals, plastics, and composites to their precise specifications, catering to diverse customer requirements.[Paragraph 5]Speaking at the product launch event, [Company Name]'s CEO expressed enthusiasm for the new innovation, stating, "The CVD Trimming Die represents a significant advancement in the field of precision trimming. Our relentless commitment to excellence and customer satisfaction has driven us to develop this groundbreaking technology that promises to revolutionize the manufacturing industry."[Paragraph 6]The introduction of the CVD Trimming Die reinforces [Company Name]'s position as an industry leader, dedicated to providing cutting-edge solutions tailored to the evolving needs of their customers. With a strong focus on research and development, the company continues to push the boundaries of innovation, solidifying its reputation for excellence.[Paragraph 7]As manufacturers seek to stay competitive in an ever-evolving market, the adoption of advanced technologies such as the CVD Trimming Die will be crucial in maintaining a competitive edge. [Company Name]'s forward-thinking approach ensures that their clients can remain at the forefront of technological advancements, enabling them to deliver superior products while optimizing their manufacturing processes.[Conclusion]Undoubtedly, the launch of the CVD Trimming Die marks a significant milestone in the manufacturing industry. By combining cutting-edge CVD technology with precision trimming processes, [Company Name] has paved the way for enhanced productivity, efficiency, and quality. This innovation cements their position as an industry leader in providing innovative die solutions, empowering manufacturers to reach new heights of success.