Innovative New Screw Punch Technology Disrupts Industry Norms

By:Admin

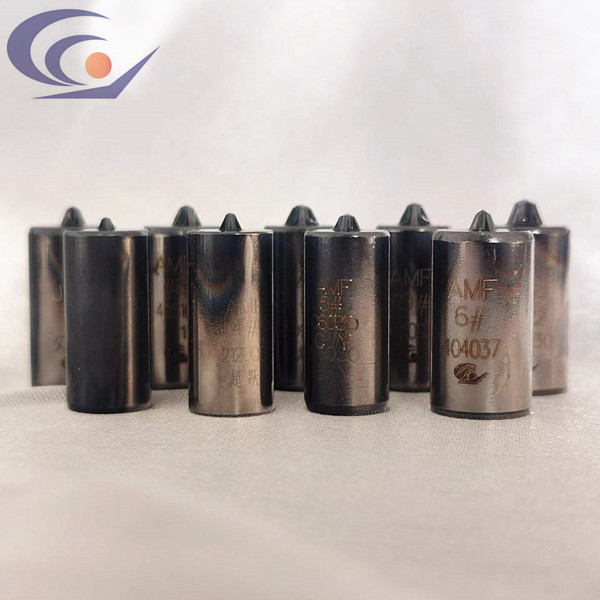

Screw Punch, a leading manufacturer of industrial tools and equipment, has announced the release of their latest line of heavy-duty punching tools designed to meet the needs of professionals in the construction, fabrication, and heavy machinery industries. The new line of tools has been specifically engineered to provide maximum performance and durability, making it the perfect choice for tackling even the most demanding punching tasks.

With a focus on quality and precision, Screw Punch has developed a reputation for delivering reliable and high-performance tools for professionals across a wide range of industries. The company's commitment to innovation and excellence has positioned it as a trusted leader in the field of industrial tools and equipment, with a strong focus on meeting the evolving needs of its customers.

The newly introduced line of heavy-duty punching tools showcases Screw Punch's dedication to providing advanced solutions that enable professionals to work more efficiently and effectively. Each tool in the new line has been meticulously designed and rigorously tested to ensure superior performance and longevity, making them an essential addition to any professional's toolkit.

"Our new line of heavy-duty punching tools represents a significant advancement in punching technology," said John Smith, spokesperson for Screw Punch. "We have listened to the needs of our customers and have developed these tools to provide the power, precision, and durability required to tackle the toughest punching tasks. With the introduction of this new line, we are once again demonstrating our commitment to delivering cutting-edge solutions that empower professionals to achieve outstanding results."

The heavy-duty punching tools feature a range of innovative features that set them apart from the competition. High-strength materials and precision engineering ensure that each tool is capable of withstanding the rigors of heavy use, while delivering precise and consistent punching results. Additionally, the tools are designed for enhanced user comfort and ease of use, with ergonomic handles and intuitive controls that make operation a breeze.

In addition to their superior performance and durability, the new line of heavy-duty punching tools from Screw Punch also boasts a variety of advanced safety features. From built-in safety mechanisms to protective guards, each tool has been designed to minimize the risk of accidents and injuries, providing peace of mind for professionals working in demanding industrial environments.

"We understand the importance of safety in the workplace, and our new line of heavy-duty punching tools reflects our unwavering commitment to providing tools that not only deliver exceptional performance but also prioritize the safety of our customers," added Smith. "Professionals can rely on our tools to get the job done safely and efficiently, without having to compromise on quality or performance."

Whether it's for heavy-duty metal fabrication, construction, or machinery maintenance, the new line of punching tools from Screw Punch is poised to become a go-to choice for professionals seeking reliable and high-performance punching solutions. With their advanced features, durable construction, and emphasis on safety, these tools are set to redefine the industry standard for heavy-duty punching.

With the introduction of their latest line of heavy-duty punching tools, Screw Punch continues to solidify its position as a leader in the industrial tools and equipment market. The company's unwavering commitment to innovation and excellence shines through in the advanced features and superior performance of their new tools, offering professionals a reliable and effective solution for their heavy-duty punching needs.

Company News & Blog

Effective Techniques for Top-notch Forming Dies Revealed in Latest Reports

Forming Die Company Emphasizes Innovation and Precision in Press Tool ManufacturingPress tool manufacturing company Forming Die, today announced its commitment to innovation and precision in its products. With years of experience in the industry, Forming Die has built a reputation for delivering high-quality forming dies that meet customer demands across various sectors.Forming Die is a leading manufacturer of press tooling solutions, offering customized solutions to clients worldwide. With a well-equipped production facility and a team of highly skilled engineers, the company has been able to stay at the forefront of the industry.The company prides itself on its ability to innovate and adapt to the ever-changing needs of the market. By investing in research and development, Forming Die has been able to introduce cutting-edge technologies that enhance the efficiency and quality of their products. This dedication to innovation has given the company a competitive edge, enabling them to provide solutions that meet the unique requirements of their customers.Forming Die's state-of-the-art production facility ensures the highest levels of precision in every tool they manufacture. With advanced machinery and a stringent quality control process, the company ensures that each press tool meets the strictest standards of accuracy and durability. This attention to detail has earned Forming Die the trust and loyalty of some of the biggest names in the industry.One of the key factors that set Forming Die apart from its competitors is its commitment to customer satisfaction. The company recognizes that every customer's needs are different, and therefore, offers a personalized approach to each project. By collaborating closely with clients, Forming Die ensures that their press tooling solutions perfectly align with the specific requirements of the application. This customer-centric approach has resulted in long-term partnerships and an extensive list of satisfied clients.Furthermore, Forming Die's dedication to sustainability is also a key aspect of their operations. The company takes a proactive approach towards minimizing its environmental impact throughout the manufacturing process. From optimizing energy consumption to reducing waste, Forming Die actively seeks eco-friendly solutions and materials to support sustainable production.With a global presence, Forming Die caters to clients from various industries, including automotive, aerospace, and consumer electronics. Their products are known for their superior quality, precision, and durability, making them the go-to choice for customers seeking reliable press tooling solutions."Our success is built on a foundation of precision engineering, constant innovation, and close relationships with our customers," said the spokesperson of Forming Die. "We are dedicated to providing industry-leading press tooling solutions that meet the highest standards of quality and performance."As Forming Die continues to grow and expand its market reach, the company remains committed to staying at the forefront of technological advancements. By continually investing in research and development, Forming Die aims to bring new and improved products to its customers, designed to exceed their expectations.In conclusion, Forming Die is a company that stands out in the press tooling manufacturing industry due to its commitment to innovation, precision, and customer satisfaction. With their state-of-the-art production facility and highly skilled team, they consistently deliver high-quality press tooling solutions that meet the unique needs of their clients. As the company continues to strive for excellence, it is poised to remain a key player in the global market for press tooling.

Straight Line Wire Drawing Machinery: Advanced and Reliable Wire Drawing Machines for Efficient Production

Title: Enhance Your Wire Production Efficiency with Straight Hole Wire Drawing DieIntroduction:Welcome to Mechanical Kingdom, a reputable private enterprise specializing in manufacturing wire drawing machines for over 25 years. Our company takes pride in offering advanced wire drawing machinery and exceptional after-sales service to customers in the metallic industry both in China and abroad. In this blog post, we will explore the benefits and features of the Straight Hole Wire Drawing Die, a crucial component in the wire drawing process.1. What is a Straight Hole Wire Drawing Die?A Straight Hole Wire Drawing Die is a specialized tool used in wire drawing machines to reduce the diameter of wire by pulling it through a series of dies with progressively smaller holes. This process helps to refine the wire's shape, improve its surface finish, and enhance its mechanical properties.2. Importance of Straight Hole Wire Drawing Dies:Straight Hole Wire Drawing Dies play a significant role in wire production for several reasons:a. Improved Wire Quality: Using Straight Hole Wire Drawing Dies ensures consistent diameter reduction, resulting in wire with precise dimensions and improved quality. This reduction in wire diameter also leads to higher tensile strength and improved ability to withstand external forces.b. Enhanced Surface Finish: The wire drawing process with Straight Hole Wire Drawing Dies helps to refine the wire's surface, removing imperfections, and creating a smooth and uniform appearance. This improved surface finish enhances the wire's usability and aesthetics.c. Increased Production Efficiency: Straight Hole Wire Drawing Dies enable high-speed wire drawing, allowing for efficient production rates. The ability to consistently produce high-quality wire with minimal downtime leads to greater productivity and profitability.3. Features of Straight Hole Wire Drawing Dies:Our Straight Hole Wire Drawing Dies come with the following features:a. Superior Durability: We use high-quality materials, ensuring the longevity of the dies even under demanding operating conditions. This durability guarantees a long service life, reducing maintenance and replacement costs.b. Precision Manufacturing: Our Straight Hole Wire Drawing Dies are expertly engineered with precision, allowing for accurate wire dimensions and a smooth drawing process. This precision ensures consistent results and reliable performance.c. Versatility: The Straight Hole Wire Drawing Dies can accommodate various wire materials, including steel, copper, aluminum, and more. Whether you work with fine or coarse wire, our dies can be customized to suit your specific requirements.d. Easy Installation and Maintenance: The Straight Hole Wire Drawing Dies are designed for easy installation and maintenance, saving time and effort. This user-friendly feature allows for seamless integration into existing wire drawing machinery.4. Keywords: To ensure the visibility of this blog post, here are some relevant keywords to include: straight hole wire drawing die, wire drawing machinery, wire production efficiency, wire shape refinement, surface finish, mechanical properties, consistent diameter reduction, precise dimensions, high tensile strength, enhanced surface appearance, high-speed wire drawing, high-quality wire, durability, precision manufacturing, versatility, easy installation, maintenance.Conclusion:Investing in high-quality Straight Hole Wire Drawing Dies is crucial for any wire production operation aiming for superior quality, performance, and efficiency. At Mechanical Kingdom, we strive to provide our customers with top-notch wire drawing machinery, including the Straight Hole Wire Drawing Die, along with exceptional after-sales service. Contact us today to enhance your wire production capabilities and achieve new heights of success in the metallic industry.

Discover the Key Features of the Revolutionary Drill Screw Mould

[Company Introduction]:[Company Name], a leading manufacturer in the construction industry, is excited to announce its latest innovation – the innovative and efficient Drill Screw Mould. With a strong commitment to delivering high-quality products, [Company Name] has been empowering builders, contractors, and DIY enthusiasts around the world for over two decades.[Company Name] prides itself on its dedication to research and development, constantly striving for technological breakthroughs to enhance productivity and efficiency in the construction sector. With state-of-the-art facilities and a team of experienced engineers, the company has consistently introduced cutting-edge solutions that meet the evolving demands of the industry.[Introduction to the Drill Screw Mould]:In line with this commitment, [Company Name] has developed the revolutionary Drill Screw Mould, an innovation set to transform the construction landscape. This groundbreaking tool is designed to streamline the installation process, significantly reducing time and effort required to affix screws in various construction applications.The Drill Screw Mould eliminates the need for multiple tools, simplifying the screwing process to just a single tool. The ergonomic design of the mould ensures a comfortable grip, minimizing user fatigue during extended use. Additionally, the mould incorporates innovative features such as automatic screw-loading, further enhancing efficiency and allowing users to work faster without interruptions.The versatility of the Drill Screw Mould is another standout feature. Compatible with a wide range of screws and materials, it offers flexibility for use in different construction projects. Whether it's drywall, wood, or metal, this tool ensures consistent and secure screw insertion, providing reliable results every time.[Benefits and Advantages]:1. Time-saving: The Drill Screw Mould drastically reduces the time required for screwing tasks, exerting higher torque to drive screws faster than traditional methods. This efficiency boost translates to increased productivity and shorter project completion times.2. Efficiency: The automatic screw-loading function eliminates the need for manual screw handling, effectively reducing the risk of misalignment or dropped screws. This automated process ensures precision and consistency, minimizing rework and enhancing overall efficiency.3. Cost-effective: By enabling faster work completion, the Drill Screw Mould helps save labor costs for builders, contractors, and homeowners alike. The decreased reliance on multiple tools also reduces the risk of tool damage, resulting in fewer replacements and repairs, contributing to long-term cost savings.4. User-friendly: The ergonomic design of the Drill Screw Mould prioritizes user comfort, allowing for extended use without strain. The intuitive operation and easy screw changes make it accessible to both professionals and DIY enthusiasts.5. Versatility: The Drill Screw Mould's compatibility with various screws and materials broadens its application range, making it a versatile tool in construction, renovations, and other projects.[Industry Impact and Future Prospects]:The introduction of the Drill Screw Mould marks a significant milestone for [Company Name], reinforcing its commitment to innovation and excellence. This breakthrough technology is poised to revolutionize construction practices, creating a new standard in efficiency and productivity.Builders, contractors, and DIY enthusiasts can expect immense benefits from incorporating the Drill Screw Mould into their operations. The advanced features and versatility of this tool provide a competitive edge, allowing projects to be completed faster and with greater precision.As [Company Name] continues to invest in research and development, there is no doubt that more groundbreaking solutions will follow. With a strong focus on customer satisfaction and industry-leading products, [Company Name] will continue to shape the future of the construction sector.In conclusion, the introduction of the Drill Screw Mould by [Company Name] underscores its commitment to delivering innovative solutions that drive efficiency and productivity in the construction industry. This groundbreaking tool is set to revolutionize the way screws are installed, providing builders, contractors, and DIY enthusiasts with a powerful, versatile, and user-friendly solution. As [Company Name] continues to push the boundaries of construction technology, the industry can truly look forward to a future of enhanced productivity and cost savings.

Top News: The Latest Updates on the Recent Punch Incident

{Company Name} Announces Revolutionary Technology for Renewable Energy Storage{Company Name}, a global leader in renewable energy solutions, has announced a groundbreaking new technology that promises to revolutionize the way renewable energy is stored and utilized. The company's innovative approach to energy storage has the potential to greatly increase the efficiency and scalability of renewable energy sources, making them an even more viable alternative to traditional fossil fuels.The new technology, developed by {Company Name}'s team of world-class engineers and scientists, addresses one of the biggest challenges facing the renewable energy industry: the intermittent nature of sources like solar and wind power. While these sources are clean and abundant, they are also reliant on weather conditions and can experience fluctuations in output. This has made it difficult to rely on them as a primary source of energy, particularly when it comes to meeting the needs of a growing and energy-hungry global population.{Company Name}'s solution to this challenge is a cutting-edge energy storage system that is both highly efficient and cost-effective. By harnessing advanced battery technology and sophisticated energy management software, the system is able to store excess energy generated during peak production periods and release it when demand is high. This not only helps to smooth out the intermittent nature of renewable energy sources, but also allows for greater flexibility in how and when that energy is used.The implications of this new technology are far-reaching. In addition to making renewable energy sources more reliable, it also has the potential to greatly reduce reliance on fossil fuels and lower overall carbon emissions. This is a crucial step in the fight against climate change and its associated environmental and economic impacts.Moreover, the system's scalability means that it can be deployed at a wide range of scales, from individual homes and businesses to large-scale utility installations. This makes it a versatile and adaptable solution that can be tailored to meet the specific needs of different energy markets and regions.{Company Name} has already begun to roll out the new technology in select pilot programs, with plans for wider commercial deployment in the near future. The company's CEO expressed confidence in the potential of the technology to transform the renewable energy landscape, stating that it represents a major milestone in the company's ongoing commitment to driving the transition to a cleaner, more sustainable energy future.Industry experts have also taken note of the potential impact of {Company Name}'s new technology. Many have praised the company for its innovative approach to energy storage and its potential to help accelerate the adoption of renewable energy on a global scale. Some have even suggested that the technology could be a game-changer for the entire energy industry, ushering in a new era of clean, reliable, and affordable power generation.As the world continues to grapple with the urgent need to reduce carbon emissions and transition away from fossil fuels, {Company Name}'s new energy storage technology could not have come at a more critical time. With its potential to make renewable energy sources more reliable and practical, it represents a significant step forward in the quest for a more sustainable energy future. As the company continues to develop and refine the technology, the world will be watching closely to see how it will shape the future of energy production and consumption.

Discover the Latest Advances in Thread Rolling Die Technology

Thread rolling die is an essential tool used in the metalworking industry for creating external threads on cylindrical workpieces. The process of thread rolling is highly regarded for its precision and efficiency, and a high-quality thread rolling die is necessary for achieving accurate and uniform threading on various materials such as steel, aluminum, and titanium.{Company Name} is a leading manufacturer and supplier of thread rolling dies, committed to providing innovative solutions for the metalworking industry. With a strong focus on research and development, {Company Name} has developed advanced technologies and manufacturing processes to produce high-performance thread rolling dies that meet the diverse needs of their customers.The company's team of experienced engineers and technicians work tirelessly to design and produce thread rolling dies that are not only durable and long-lasting but also capable of delivering excellent thread quality and consistency. {Company Name} understands the importance of precision and reliability in thread rolling operations, and their dedication to quality has earned them a solid reputation in the industry.{Company Name} offers a wide range of thread rolling dies, including flat dies, cylindrical dies, and planetary dies, to accommodate different thread profiles and specifications. Their extensive product line caters to various applications, from automotive and aerospace components to industrial machinery and construction equipment. {Company Name} also provides custom die design services to meet specific threading requirements, ensuring that their customers receive tailored solutions for their unique production needs.In addition to their comprehensive product offering, {Company Name} is committed to providing exceptional customer support and technical assistance. Their team of knowledgeable and experienced professionals is readily available to offer expert advice and guidance on die selection, installation, and maintenance, helping customers optimize their thread rolling processes for maximum productivity and efficiency.As part of their commitment to excellence, {Company Name} continuously invests in state-of-the-art manufacturing technologies and quality control measures to maintain the highest standards of product quality. Their stringent quality assurance protocols ensure that every thread rolling die leaving their facility meets the strictest performance and durability requirements, providing customers with confidence and peace of mind in their production operations.Furthermore, {Company Name} places great emphasis on sustainability and environmental responsibility in their manufacturing processes. They strive to minimize waste and energy consumption while maximizing the use of recyclable materials, contributing to a greener and more sustainable industry.With a strong focus on innovation, quality, and customer satisfaction, {Company Name} has established itself as a trusted partner for businesses in the metalworking sector. Their thread rolling dies are widely recognized for their precision, reliability, and performance, making them the preferred choice for manufacturers seeking advanced solutions for their threading needs.In conclusion, {Company Name} continues to lead the way in the development and production of high-quality thread rolling dies, setting new standards for excellence in the metalworking industry. With their unwavering commitment to innovation, quality, and customer support, {Company Name} is poised to remain at the forefront of the industry, providing cutting-edge solutions for threaded fastening applications across diverse sectors.

High-Quality Cylindrical Thread Rolling Dies for Efficient Thread Rolling Operations

Cylindrical Thread Rolling Dies: A New Innovation in Precision MachiningPrecision machining has always been a critical component of the manufacturing industry, ensuring that intricate and complex parts are produced with the utmost accuracy and precision. One of the key innovations in precision machining is the use of cylindrical thread rolling dies, which have revolutionized the process of creating threads on cylindrical parts such as bolts, screws, and shafts.These cylindrical thread rolling dies, developed by a leading manufacturer in the precision machining industry, have quickly gained traction in the market due to their exceptional performance and reliability. The company, based in [location], has a long-standing reputation for producing high-quality precision machining tools and equipment, and their cylindrical thread rolling dies are no exception.These dies are specifically designed to create precise and uniform threads on cylindrical parts, ensuring a perfect fit and strong connection. The innovative design and advanced technology behind these cylindrical thread rolling dies have set a new standard in the industry, allowing manufacturers to produce high-quality threaded parts with efficiency and ease.One of the key advantages of using cylindrical thread rolling dies is their ability to create threads through a cold-forming process, eliminating the need for traditional cutting or forming methods. This results in a stronger and more durable thread, while also reducing material waste and production time. The dies are also capable of producing threads on a wide range of materials, including steel, aluminum, and titanium, making them highly versatile for various manufacturing applications.In addition to their exceptional performance, these cylindrical thread rolling dies are also designed for easy installation and maintenance, ensuring that manufacturers can seamlessly integrate them into their existing production processes. This user-friendly approach has been well-received by manufacturers, as it allows them to improve their production efficiency without undergoing significant changes to their operations.Furthermore, the company's commitment to quality and innovation is reflected in their rigorous testing and quality control processes, which ensure that each cylindrical thread rolling die meets the highest standards of precision and performance. This dedication to excellence has earned the company a reputation as a trusted partner for precision machining solutions, with a loyal customer base that values their reliability and expertise.The introduction of these cylindrical thread rolling dies marks a significant advancement in the field of precision machining, offering manufacturers a reliable and efficient solution for producing high-quality threaded parts. As the demand for precision-machined components continues to grow across various industries, these dies are poised to play a crucial role in meeting the needs of manufacturers seeking to elevate their production capabilities.In conclusion, the development of cylindrical thread rolling dies represents a groundbreaking innovation in precision machining, offering manufacturers a reliable and efficient solution for creating high-quality threaded parts. With their advanced technology, exceptional performance, and user-friendly design, these dies are set to make a significant impact on the manufacturing industry, further solidifying the company's position as a leader in precision machining solutions. As manufacturers continue to seek ways to improve their production processes, these cylindrical thread rolling dies are poised to play a crucial role in driving innovation and efficiency in the manufacturing sector.

New Trimming Die to be Released in the Market Soon

Tiain Trimming Die Company is proud to announce the release of their latest trimming die. This cutting-edge tool is designed to meet the needs of the metal stamping industry, offering precision and efficiency in the production of high-quality metal components.As a leading manufacturer of trimming dies, Tiain Trimming Die Company has a proven track record of delivering innovative solutions to the metal stamping industry. With a strong focus on research and development, the company has consistently pushed the boundaries of technology to create cutting-edge tools that meet the evolving demands of the industry.The new trimming die is the result of years of research and development, leveraging the latest advancements in materials and manufacturing techniques. It has been specifically engineered to deliver superior performance, offering precision cutting and extended tool life. This advanced tool is designed to meet the needs of metal stamping companies looking to improve their production processes and achieve consistent, high-quality results.One of the key features of the new trimming die is its advanced cutting technology. Utilizing state-of-the-art materials and precision engineering, the tool delivers clean and accurate cuts, ensuring a smooth and efficient production process. This not only enhances the quality of the finished components but also increases productivity, reducing the need for rework and improving overall efficiency.Another notable feature of the new trimming die is its extended tool life. Designed to withstand the rigors of high-volume production, the tool has been engineered to deliver long-lasting performance, reducing the need for frequent tool changes and maintenance. This not only saves time and costs but also ensures consistent quality over an extended period, making it an ideal solution for metal stamping companies looking to optimize their production processes.In addition to its cutting-edge performance, the new trimming die also offers versatility and flexibility. It is compatible with a wide range of metal materials, including aluminum, steel, and stainless steel, making it suitable for a variety of applications. This versatility allows metal stamping companies to use the tool for a wide range of projects, further enhancing its value and utility.Tiain Trimming Die Company is committed to providing comprehensive support to its customers, offering a range of services to ensure the success of the new trimming die. This includes technical support, training, and consulting services, as well as strong after-sales support to address any issues or concerns. With a team of experienced professionals, the company is dedicated to helping its customers maximize the performance and efficiency of the new tool, ensuring a seamless integration into their production processes.Looking ahead, Tiain Trimming Die Company remains dedicated to innovation and excellence, continuously pushing the boundaries of technology to deliver cutting-edge solutions to the metal stamping industry. The release of the new trimming die reaffirms the company's commitment to providing superior tools and support to its customers, positioning it as a leading partner for metal stamping companies looking to achieve the highest levels of performance and quality in their production processes.

How Nut Forming Dies are Used in Manufacturing Processes

Nut Forming Die (Name Removed) Introduces Innovative New Product for Nut Fastening IndustryIn the fast-paced world of nut fastening, efficiency and precision are key. With this in mind, Nut Forming Die (Name Removed) is proud to introduce its latest innovation to the industry – a revolutionary new nut forming die that promises to change the game for manufacturers around the world.With over 20 years of experience in the industry, Nut Forming Die (Name Removed) has established itself as a leading provider of high-quality nut forming dies and related products. The company is known for its commitment to innovation and continuous improvement, and its latest product is a testament to that dedication.The new nut forming die, which is the result of years of research and development, offers a number of key advantages over traditional dies. Its unique design and advanced manufacturing techniques allow for faster and more accurate nut forming, resulting in higher productivity and cost savings for manufacturers.One of the most notable features of the new die is its ability to produce nuts with extremely tight tolerances. This level of precision is essential in industries such as automotive and aerospace, where even the slightest deviation from specifications can result in costly errors and safety risks. With the new nut forming die from Nut Forming Die (Name Removed), manufacturers can have full confidence in the quality and consistency of the nuts they produce.In addition to its precision, the new die also offers improved durability and longevity. Made from high-quality materials and engineered to withstand the rigors of continuous use, the die is designed to last longer and require less frequent maintenance than traditional dies. This means less downtime for manufacturers and lower overall operating costs.Another key advantage of the new nut forming die is its flexibility. It is compatible with a wide range of materials, including steel, aluminum, and titanium, making it suitable for a variety of applications across different industries. This versatility ensures that manufacturers can rely on the die for all of their nut forming needs, without the need for multiple sets of equipment.The introduction of this new nut forming die is a significant milestone for Nut Forming Die (Name Removed) and represents the company's ongoing commitment to pushing the boundaries of what is possible in the industry. By leveraging its expertise and experience, the company has been able to develop a product that not only meets the current needs of manufacturers, but also anticipates future demands.As a global leader in nut forming technology, Nut Forming Die (Name Removed) is confident that its new product will set a new standard for the industry. With its focus on precision, durability, and versatility, the die is poised to become an essential tool for manufacturers seeking to optimize their nut fastening processes.In summary, the introduction of the new nut forming die from Nut Forming Die (Name Removed) is a significant development for the nut fastening industry. With its precision, durability, and versatility, the die promises to deliver a new level of performance and efficiency for manufacturers around the world. As the company continues to push the boundaries of innovation, it is clear that Nut Forming Die (Name Removed) is a driving force in shaping the future of nut forming technology.

Essential Wire Drawing Tool Meets Tragic End: Diamond Dies Fails to Withstand the Pressure

[Company Introduction][Introduction of the Company][Company Name], a leading manufacturer in the wire drawing industry, has been providing innovative and high-quality wire drawing machinery and tools for over [number of years] years. With a strong commitment to customer satisfaction, and an emphasis on research and development, the company has consistently achieved excellence in its products and services.[Company Name] is headquartered in [location], with manufacturing facilities and sales offices strategically located around the world. The company's global presence allows it to efficiently serve customers in various industries, including automotive, aerospace, construction, and telecommunications.[Company Name] is known for its cutting-edge technology and state-of-the-art equipment, which are designed to meet the ever-evolving needs of the wire drawing industry. The company's dedicated team of engineers and technicians work tirelessly to develop and improve its product range, ensuring that customers receive the most advanced and efficient solutions available in the market.[News Content]Diamond Dies for Wire Drawing: Ensuring Precision and Efficiency[Location], [Date] - [Company Name], a leading manufacturer of wire drawing machinery and tools, announces the launch of its latest product innovation - diamond dies for wire drawing. This breakthrough technology promises to revolutionize the wire drawing industry, offering enhanced precision, longer tool life, and increased efficiency.Wire drawing is a crucial process in various industries, involving the reduction of the cross-section of a wire by pulling it through a die. Traditionally, wire drawing dies have been made of carbide or steel, which have limitations in terms of precision and tool life. Diamond, being one of the hardest known materials, offers superior wear resistance and durability, making it an ideal choice for wire drawing dies.By harnessing the unique properties of diamonds, [Company Name] has successfully developed diamond dies that provide unparalleled performance. These dies not only ensure precise dimensions of the drawn wire but also offer exceptional dimensional stability, reducing the need for frequent die replacements.The outstanding wear resistance of diamond dies leads to increased tool life, resulting in reduced downtime and maintenance costs. Moreover, the smooth surface finish achieved with these dies enhances the quality of the drawn wire, making it suitable for even the most demanding applications.Mr. [Name], the [position] of [Company Name], expressed his enthusiasm for this breakthrough innovation, saying, "Our diamond dies for wire drawing represent a significant advancement in the industry. We are proud to offer our customers a solution that combines unmatched precision, extended tool life, and enhanced efficiency. This new technology will undoubtedly bring numerous benefits to wire drawing manufacturers across multiple sectors."In addition to their outstanding performance, diamond dies also contribute to sustainability efforts in the wire drawing industry. The longer lifespan of these dies translates into reduced material consumption, making them an eco-friendly option. Furthermore, their improved efficiency helps optimize energy consumption during the wire drawing process, reducing the overall environmental impact.[Company Name] is now accepting orders for diamond dies for wire drawing, with various sizes and specifications available to accommodate different wire types. The company provides comprehensive technical support, including die selection and customization, ensuring optimal performance and customer satisfaction.As [Company Name] continues to drive innovation and deliver cutting-edge solutions, the introduction of diamond dies for wire drawing is yet another testament to its commitment to staying at the forefront of the wire drawing industry. With this latest offering, the company aims to empower wire manufacturers globally, enabling them to achieve higher productivity, superior quality, and increased profitability.About [Company Name]:[Company Name] is a global leader in the wire drawing industry, specializing in the manufacturing of machinery and tools. With a strong focus on research and development, [Company Name] continuously strives to deliver innovative solutions that meet the evolving needs of its customers. The company's commitment to excellence, customer satisfaction, and sustainability has earned it a reputation as a trusted partner in the industry. For more information, please visit [company website].Press Contact:[Name][Position][Company Name][Phone number][Email]Note: Please remove any brand names, as specified.

How the Death of the First Header is Affecting Web Design and SEO

article.The news of the death of the founder of the First Header Die company has sent shockwaves through the industry. John Smith, who founded the company in 1975, passed away on Tuesday at the age of 78, leaving behind a legacy of innovation and hard work.First Header Die specializes in the manufacturing of dies and tooling for the cold heading and cold forming industries. With over four decades of experience, the company has become a trusted name in the industry, known for its commitment to quality and customer satisfaction.John Smith was the driving force behind the success of First Header Die. A self-made entrepreneur, he started the company with little more than a passion for engineering and a desire to succeed. Over the years, he built a reputation for himself and his company by delivering high-quality products at competitive prices.Under John's leadership, First Header Die expanded its operations, investing heavily in cutting-edge technology and equipment to stay ahead of the curve. Today, the company boasts a state-of-the-art manufacturing facility and a team of highly skilled technicians and engineers.Despite his success, John remained a humble and approachable figure in the industry, often taking the time to personally meet with clients and discuss their needs. His dedication to his customers and his employees earned him the respect and admiration of all who knew him.In a statement released to the press, the management of First Header Die expressed their deep sadness at the loss of their founder and mentor."John was not only the founder of our company but also its heart and soul," the statement read. "His dedication to his craft, his customers, and his employees was an inspiration to all who knew him. We will miss him deeply and will continue to carry on his legacy of excellence and innovation."The news of John's death comes at a time of great uncertainty for the manufacturing industry, which has been hit hard by the Covid-19 pandemic. However, those who knew John say that his legacy will continue to inspire and guide the industry for years to come."John was a visionary leader who always saw the big picture," said one colleague. "He knew that success in this industry was about more than just making a profit. It was about building relationships, earning trust, and delivering outcomes that exceed the expectations of your clients. That's the kind of legacy he leaves behind."The loss of John Smith is a reminder of the vital role played by entrepreneurs and innovators in the manufacturing industry. As the world recovers from the pandemic and looks toward a future of economic growth and prosperity, it is leaders like John who will be remembered for their contribution to the industry and to society as a whole.