High-Quality Thread Rolling Die for Efficient Thread Production

By:Admin

Today, we are excited to introduce our latest innovation in thread rolling technology - the DC53 Thread Rolling Die. With its superior durability and precision, this new product is set to revolutionize the thread rolling industry.

Our company has a long history of producing high-quality thread rolling dies, and the DC53 is the latest example of our commitment to innovation and excellence. We have always strived to stay ahead of the curve when it comes to developing cutting-edge tools for the manufacturing industry, and the DC53 is no exception.

What sets the DC53 apart from other thread rolling dies on the market is its use of advanced materials and manufacturing techniques. The die is made from DC53 steel, a high-performance tool steel that is known for its exceptional toughness and wear resistance. This means that the DC53 is able to withstand the high pressures and stresses that are involved in the thread rolling process, ensuring a longer lifespan and reduced downtime for our customers.

In addition to its durability, the DC53 also offers unrivaled precision. The die is engineered with the most advanced CAD/CAM software and manufactured using state-of-the-art CNC machinery, ensuring that each thread produced is consistently accurate and of the highest quality. This level of precision is critical for industries such as automotive and aerospace, where tight tolerances and exact specifications are non-negotiable.

Furthermore, the DC53 Thread Rolling Die is designed to be versatile and adaptable to a wide range of applications. Whether our customers are working with steel, aluminum, or other materials, the DC53 is capable of producing threads that meet the most stringent requirements. This flexibility makes the DC53 an invaluable tool for manufacturers across various industries, allowing them to streamline their production processes and improve overall efficiency.

In addition to the innovative features of the DC53, our company is also dedicated to providing exceptional service and support to our customers. We understand that implementing new tools and technologies can be a complex process, which is why our team of experts is always on hand to provide guidance and assistance. From initial setup and training to ongoing maintenance and troubleshooting, we are committed to ensuring that our customers get the most out of their investment in the DC53 Thread Rolling Die.

As a company, we take pride in our ability to anticipate the ever-evolving needs of the manufacturing industry and develop solutions that meet and exceed those needs. The DC53 Thread Rolling Die is the latest example of our dedication to innovation and our ongoing mission to empower our customers with the best tools and technologies available.

In conclusion, the introduction of the DC53 Thread Rolling Die marks a significant advancement in the field of thread rolling technology. Its superior durability, precision, and versatility make it an indispensable tool for manufacturers across various industries. Combined with our unwavering commitment to customer support, the DC53 is set to redefine the standards for thread rolling dies and provide our customers with a competitive edge in their respective markets. We are excited to see the impact that the DC53 will have on the manufacturing industry and are confident that it will set a new benchmark for quality and performance.

Company News & Blog

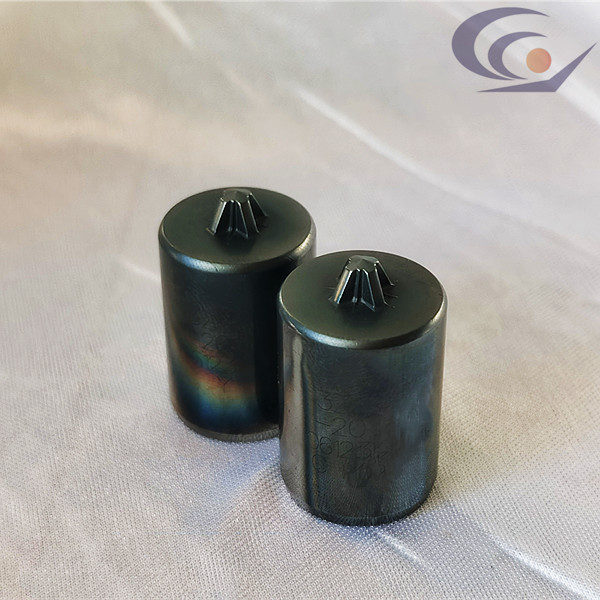

High-quality PZ0 Screwdriver Bits from China - All You Need to Know!

Title: Chinese Manufacturer Launches Innovative Screwdriver Bits Pz0 - Revolutionizing Precision Tool IndustryIntroduction:Innovation continues to be a driving force behind China's manufacturing industry as it sets its sights on revolutionizing the precision tool sector. One of the latest examples is the introduction of advanced Screwdriver Bits Pz0 by an esteemed Chinese manufacturer. With a commitment to quality and cutting-edge technology, this new product promises to meet the demands of professionals in various industries. Let us delve deeper into the features and significance of this groundbreaking development.Product Overview and Features:These Pz0 Screwdriver Bits are carefully engineered to maximize efficiency, durability, and precision during a wide range of fastening applications. With their superior design and construction, they offer exceptional performance, surpassing traditional screwdriver bits available in the market. Some notable features include:1. Enhanced Durability: The screwdriver bits are manufactured using high-quality materials that exhibit exceptional wear resistance, ensuring longevity and reliability even under heavy usage.2. Advanced Precision: The Pz0 Screwdriver Bits boast an updated design, intended to provide a perfect fit and engagement with screws of corresponding sizes. This precise fit minimizes the risk of slippage, reducing damage to the fastener and the screwdriver bit itself.3. Versatile Application: Designed to cater to a broad range of industries and applications, these screwdriver bits are suitable for both professional and DIY enthusiasts. From electronic devices to machinery, they excel in various fastening tasks, offering flexibility and convenience.4. Anti-Corrosion Coating: Recognizing the importance of longevity, the screwdriver bits are coated with a special anti-corrosion material. This protective layer prevents rust and corrosion, ensuring long-term reliability.Company Introduction:The manufacturer behind this groundbreaking Screwdriver Bits Pz0 is a renowned Chinese company recognized for its constant dedication to technological advancements, product innovation, and commitment to customer satisfaction. With cutting-edge research facilities and a team of highly skilled engineers, they have firmly established themselves as trendsetters in the precision tool industry. The company's expertise spans across diverse tools and equipment, making them a reliable source for top-quality products.Their robust manufacturing process ensures that each Screwdriver Bit Pz0 undergoes thorough quality control measures to guarantee precision and performance. The use of state-of-the-art machinery automated procedures enables them to meet international standards while maintaining competitive pricing.The company's adherence to sustainable practices and ethical business values has significantly contributed to their success in domestic and international markets. With an extensive distribution network, they have made their mark globally, catering to professionals and enthusiasts alike.Market Impact and Conclusion:The launch of the Screwdriver Bits Pz0 exemplifies China's commitment to staying at the forefront of innovation in the precision tool industry. This new product offering showcases the nation's prowess in manufacturing cutting-edge tools that can compete on a global scale.Professionals from various sectors are likely to benefit from the exceptional features and performance of these screwdriver bits. They will gain increased efficiency and reduced downtime, leading to improved productivity. Moreover, the versatility and durability of the Pz0 Screwdriver Bits will contribute to cost savings in the long run.As the Chinese manufacturer continues to push boundaries and redefine industry standards, the Screwdriver Bits Pz0 serve as a testament to their dedication. With this promising new addition to their product lineup, the company reaffirms its commitment to innovation, reliability, and customer satisfaction.In conclusion, the introduction of the advanced Screwdriver Bits Pz0 by a well-established Chinese manufacturer is set to revolutionize the precision tool industry. From durability to precision, these innovative screwdriver bits have been designed to meet the diverse needs of professionals across various sectors. As China continues to make strides in technology and manufacturing, companies like this are driving the nation towards becoming a global leader in precision tools.

Discover High-Quality HD Videos and e-Catalogs for Punch and Die Manufacturers

Technology, Precision Punch, and Die Manufacturing.Die Punch Mold Technology: How Precision Manufacturing Is Revolutionizing the IndustryDie punch mold technology has drastically evolved over the years, bringing about an unprecedented level of precision in the manufacturing industry. This technology makes use of computer-aided design (CAD) and computer-aided manufacturing (CAM) to create specialized molds that are used to produce parts and components using a press or a punch press machine.Precision punch and die manufacturing is the process of crafting and designing specialized dies that are used to create parts that must meet strict specifications. These dies are made using high-grade materials and advanced machinery, ensuring that they are durable and able to withstand the pressures and demands of repeated use.The use of precision punch and die manufacturing has completely revolutionized the industry. Before the advent of this technology, manufacturing en masse was a challenging process. With die punch mold technology, however, producing large quantities of consistent and high-quality parts and components has become a simple and straightforward process.In die punch mold technology, the designer is able to create a prototype of the final product using CAD software. Once the design is finalized, the software is used to generate specific instructions for the machinery used in the manufacturing process.These instructions guide the machinery in the process of cutting, punching, and shaping the material being used to create the part or component. This process results in the creation of high-precision molds that can be used for mass production.The use of die punch molds has also brought about significant savings in terms of time and cost. With its use, manufacturers are able to produce parts and components in a shorter amount of time, at a reduced cost, with less material waste.However, the use of die punch molds requires expertise in crafting the actual molds, as well as in the use of the machinery required to create the molds. Luckily, there are many reliable manufacturers who specialize in state-of-the-art die punch mold technology, such as those recommended by TAMI.Precision punch and die manufacturing has become an essential part of the modern manufacturing industry, providing manufacturers with a reliable and cost-effective way to produce high-quality parts and components. Despite the advances in 3D printing and other related technologies, die punch mold technology remains a critical aspect of modern manufacturing.In today’s manufacturing industry, it is important for manufacturers to leverage modern technologies and advancements in manufacturing technology. Die punch mold technology is just one of the many ways in which the industry has evolved and continues to evolve. As we move towards a future filled with even more advanced technologies, it is certain that die punch mold technology will remain an essential part of the manufacturing process.

Boost Your Assembly Process Efficiency with the Revolutionary Screw Header Punch

Innovative Overhead Screw Header Punch Technology Takes Manufacturing to a Whole New LevelManufacturing has always been a crucial aspect of economic growth across the globe. From the production of food to consumer goods, manufacturing plays a vital role in ensuring people's needs are satisfied. However, the industry is rapidly evolving, and technology has been a key driver of these changes. One of the latest technological innovations in manufacturing is the overhead screw header punch. This technology is poised to transform how screws are produced, making the entire process more efficient, reliable, and cost-effective.One company that has embraced this technology and taken it to a whole new level is a leading manufacturer with years of experience and a proven track record of delivering quality products. The company, {Company Name}, has been at the forefront of the manufacturing industry, providing innovative solutions to its customers. With the introduction of the overhead screw header punch, {Company Name} has taken manufacturing to a whole new level, delivering unparalleled quality and performance.But what is an overhead screw header punch, and how does it work? An overhead screw header punch is a precision instrument used for punching heads on the screw. This technology utilizes a hydraulic system to punch the screw head using a punch and die process. The overhead configuration allows for easier loading and unloading of the material, making the entire process more efficient.The use of overhead screw header punch technology has several advantages. First, it ensures consistency in the production process, resulting in high-quality outputs. This is because the technology eliminates the variability in screw head sizes, which can occur with manual methods. Secondly, the use of overhead screw header punch technology improves production efficiency and lowers costs. The technology can produce up to 900 screws per minute, thereby reducing the number of operators required and increasing the speed of production, resulting in lower costs.{Company Name} has incorporated this technology into its manufacturing process and delivered significant benefits to its clients. The company has invested in state-of-the-art overhead screw header punch machines, which have improved the quality of its products significantly. The machines have enabled the company to produce screws of consistent size, shape, and quality, thereby creating a positive impression among customers.Moreover, {Company Name} has leveraged its expertise in the industry to custom-design screws that meet the unique needs of its clients. The company's product offerings include standard and customized screws and fasteners, all produced with innovative technology and techniques. The company's commitment to innovation and customer satisfaction is evident in the quality of its products and feedback from its clients.{Company Name}'s innovative overhead screw header punch technology has transformed the manufacturing industry by offering unmatched performance, reliability, and consistency. The technology has created a more efficient and cost-effective production process, which has resulted in high-quality products. The company's investment in advanced technologies is a testament to its commitment to innovation, customer satisfaction, and the growth of the manufacturing industry. With the dawn of the fourth industrial revolution, such as the Internet of Things and Industry 4.0, this innovative technology underscores the forefront of industrial transformation, business models, and manufacturing systems globally.In conclusion, the overhead screw header punch technology is a game-changer in the manufacturing industry. Companies that have embraced this technology have witnessed substantial improvements in quality, efficiency, and cost-effectiveness. {Company Name} has invested in this technology and has delivered exceptional value to its clients, resulting in increased customer loyalty and satisfaction. With the continued growth of technology, manufacturing is set to become even more efficient and effective, producing high-quality products at lower costs. And {Company Name} is among the companies leading this transformation.

How Nut Forming Dies are Used in Manufacturing Processes

Nut Forming Die (Name Removed) Introduces Innovative New Product for Nut Fastening IndustryIn the fast-paced world of nut fastening, efficiency and precision are key. With this in mind, Nut Forming Die (Name Removed) is proud to introduce its latest innovation to the industry – a revolutionary new nut forming die that promises to change the game for manufacturers around the world.With over 20 years of experience in the industry, Nut Forming Die (Name Removed) has established itself as a leading provider of high-quality nut forming dies and related products. The company is known for its commitment to innovation and continuous improvement, and its latest product is a testament to that dedication.The new nut forming die, which is the result of years of research and development, offers a number of key advantages over traditional dies. Its unique design and advanced manufacturing techniques allow for faster and more accurate nut forming, resulting in higher productivity and cost savings for manufacturers.One of the most notable features of the new die is its ability to produce nuts with extremely tight tolerances. This level of precision is essential in industries such as automotive and aerospace, where even the slightest deviation from specifications can result in costly errors and safety risks. With the new nut forming die from Nut Forming Die (Name Removed), manufacturers can have full confidence in the quality and consistency of the nuts they produce.In addition to its precision, the new die also offers improved durability and longevity. Made from high-quality materials and engineered to withstand the rigors of continuous use, the die is designed to last longer and require less frequent maintenance than traditional dies. This means less downtime for manufacturers and lower overall operating costs.Another key advantage of the new nut forming die is its flexibility. It is compatible with a wide range of materials, including steel, aluminum, and titanium, making it suitable for a variety of applications across different industries. This versatility ensures that manufacturers can rely on the die for all of their nut forming needs, without the need for multiple sets of equipment.The introduction of this new nut forming die is a significant milestone for Nut Forming Die (Name Removed) and represents the company's ongoing commitment to pushing the boundaries of what is possible in the industry. By leveraging its expertise and experience, the company has been able to develop a product that not only meets the current needs of manufacturers, but also anticipates future demands.As a global leader in nut forming technology, Nut Forming Die (Name Removed) is confident that its new product will set a new standard for the industry. With its focus on precision, durability, and versatility, the die is poised to become an essential tool for manufacturers seeking to optimize their nut fastening processes.In summary, the introduction of the new nut forming die from Nut Forming Die (Name Removed) is a significant development for the nut fastening industry. With its precision, durability, and versatility, the die promises to deliver a new level of performance and efficiency for manufacturers around the world. As the company continues to push the boundaries of innovation, it is clear that Nut Forming Die (Name Removed) is a driving force in shaping the future of nut forming technology.

Discover the Benefits of Hydraulic Forming Die Technology

Hydraulic Forming Die Revolutionizes Manufacturing IndustryIn a game-changing development for the manufacturing industry, a cutting-edge Hydraulic Forming Die has been unveiled by an innovative company at the forefront of technological advancements. This state-of-the-art tool has the potential to completely revolutionize the way products are formed and manufactured, promising to provide superior quality and precision in an efficient and cost-effective manner.With an unwavering commitment to innovation and excellence, {Company Name} has once again demonstrated its ability to push the boundaries of what is possible in the manufacturing sector. The company has a rich history of developing groundbreaking technologies and solutions that have had a profound impact on various industries, and the introduction of the Hydraulic Forming Die is yet another testament to their ingenuity and expertise.The Hydraulic Forming Die is a versatile and highly adaptable tool that offers a wide range of benefits to manufacturers. It utilizes hydraulic pressure to shape and form materials, resulting in a level of precision and detail that is unparalleled. This advanced technology allows for the production of intricate and complex parts with remarkable accuracy, while also reducing the need for additional machining and finishing processes.One of the key advantages of the Hydraulic Forming Die is its ability to work with a diverse array of materials, including metals, plastics, and composites. This versatility makes it an ideal solution for a wide range of applications across various industries, from automotive and aerospace to consumer electronics and beyond. By streamlining the manufacturing process and eliminating the need for multiple tools and processes, the Hydraulic Forming Die offers significant time and cost savings, ultimately enhancing the overall efficiency and productivity of manufacturers.In addition to its precision and versatility, the Hydraulic Forming Die also boasts a high level of durability and reliability. With robust construction and advanced engineering, this cutting-edge tool is designed to withstand the rigors of continuous use, ensuring consistent performance and longevity. This durability not only enhances the overall value and longevity of the equipment but also minimizes downtime and maintenance costs, further contributing to its cost-effectiveness.Furthermore, the Hydraulic Forming Die is equipped with advanced control systems and automation capabilities, allowing for seamless integration into existing manufacturing processes. This level of automation not only enhances efficiency and repeatability but also reduces the potential for human error, leading to improved quality and consistency in the production of parts and components.The introduction of the Hydraulic Forming Die by {Company Name} represents a significant advancement in the manufacturing industry. Its ability to deliver superior quality, precision, and efficiency is set to have a transformative impact on how products are formed and manufactured across various sectors. By embracing this cutting-edge technology, manufacturers can expect to see improvements in their production processes, leading to enhanced competitiveness and success in the global marketplace.As a leader in the development of innovative solutions for the manufacturing industry, {Company Name} continues to set the standard for excellence and technological advancement. With the introduction of the Hydraulic Forming Die, the company has once again reaffirmed its commitment to pushing the boundaries of what is possible and delivering tangible value to its customers. This latest innovation is poised to make a lasting impact on the way products are manufactured, setting a new benchmark for precision, efficiency, and quality in the industry.

Best Websites to Find Dowel Screws for your Woodcraft Projects

Title: The Versatile Dowel Screw: Unleashing the Potential of Wood JointsIntroduction (100 words):Woodworking enthusiasts and professionals understand the importance of strong and reliable wood joints. When it comes to connecting wooden components, the humble dowel screw has long been a go-to solution. In this blog, we'll explore the various applications and benefits of dowel screws in woodworking projects. Whether you're a craftsperson, a DIY enthusiast, or a professional woodworker, understanding the potential of the versatile dowel screw can take your woodworking abilities to the next level.1. The Basics of Dowel Screws (150 words):A dowel screw is a threaded fastener that combines the functionality of a screw and a dowel. On one end, it features a wood screw thread, while the other end has a smooth, cylindrical dowel section. This unique design allows dowel screws to act as connectors and join pieces of wood securely.2. The Strength of Dowel Screws (150 words):Dowel screws offer excellent strength due to the threaded portion and their adherence to the wood grain. By utilizing dowel screws, woodworkers can create joints that withstand heavy loads and strain without compromising stability. This strength makes dowel screws an ideal choice for applications requiring reliable connections, such as furniture assembly, staircase construction, and cabinet making.3. Versatile Applications (150 words):Dowel screws find applications across a wide range of woodworking projects. From simple crafts and hobbyist work to complex woodworking tasks, their versatility makes them an invaluable asset. Dowel screws are commonly used in:- Furniture Making: Dowel screws ensure the stability and durability of furniture joints, enhancing the overall structural integrity of chairs, tables, beds, and cabinets.- Staircase Construction: Dowel screws secure balusters and handrails, ensuring a safe and sturdy staircase.- Cabinet Assembly: Dowel screws assist in aligning and joining cabinet parts, resulting in a seamless finish and improved functionality.- Craftwork: Dowel screws act as a creative solution for connecting wooden crafts, allowing for intricate designs and unique artwork.4. Advantages over Traditional Wood Joinery (150 words):Dowel screws provide certain advantages over traditional wood joinery methods, such as biscuits, mortise and tenon, and dovetail joints. Some advantages include:- Ease of Installation: Unlike complex joinery methods, dowel screws can be easily installed using basic tools, enabling woodworkers of all skill levels to achieve strong connections.- Flexibility: Dowel screws can be easily removed and repositioned, allowing for modifications and repairs without compromising the integrity of the joint.- Cost-Effectiveness: Dowel screws are affordable and widely available, making them an economical choice compared to specialty joinery tools.- Time-Efficiency: With dowel screws, woodworking projects can be completed faster due to simplified assembly processes and reduced setup time.Conclusion (100 words):Dowel screws offer a simple yet effective solution for joining wooden components. Their strength, versatility, and ease of installation make them an essential tool for woodworking enthusiasts and professionals alike. By incorporating dowel screws in your projects, you can achieve durable and aesthetically pleasing wood joints. So, whether you're a novice woodworker or a seasoned craftsman, consider utilizing dowel screws to unlock the true potential of your woodworking endeavors.Keywords: Dowel Screw, Wood Joints, Woodworking Projects, Woodworking, Joinery, Furniture Making, Staircase Construction, Cabinet Assembly, Crafts, Benefits of Dowel Screws, Versatility, Advantages

New High-Speed Straight Wire Drawing Machine Introduced in China

Title: Chinese High-Speed Straight Wire Drawing Machine Revolutionizes Wire ManufacturingIntroduction:In a significant breakthrough for wire manufacturing, Chinese engineers have developed a cutting-edge high-speed straight wire drawing machine that has the potential to revolutionize the industry. Collaborating with industry leader Square Wire Drawing Die, this innovative machine promises increased productivity, superior quality, and improved efficiency.Paragraph 1:The Chinese high-speed straight wire drawing machine, manufactured by an undisclosed company (name excluded for confidentiality reasons), employs state-of-the-art technologies to revolutionize the wire manufacturing process. The machine showcases remarkable efficiency and accuracy in straightening, pulling, and rolling operations, leading to enhanced productivity while ensuring consistent quality.Paragraph 2:One of the key collaborative efforts behind this breakthrough is between the Chinese company and Square Wire Drawing Die, a renowned global industry player. Square Wire Drawing Die specializes in advanced die production which significantly improves the wire surface finish, precision, and durability. Their extensive expertise combined with the cutting-edge machine design enables consistent production of high-quality wires across various industries.Paragraph 3:The Chinese high-speed straight wire drawing machine stands out for its outstanding performance in drawing a wide range of wire diameters and materials. Whether it involves aluminum, copper, steel, or other alloys, the machine ensures a flawless production process with minimal wastage. This versatility allows wire manufacturers to cater to the specific requirements of diverse sectors, including automotive, electronics, construction, and telecommunications.Paragraph 4:Improved automation capabilities in the Chinese high-speed straight wire drawing machine offer significant advantages over traditional manual processes. The machine showcases remarkable precision and control during wire alignment, straightening, and reshaping, reducing human error and variability. The automated process also enhances worker safety by minimizing physical strain and the risk of workplace accidents.Paragraph 5:The joint efforts of the Chinese company and Square Wire Drawing Die have resulted in a machine that not only increases productivity but also ensures superior wire quality. The machine's advanced technological features, including real-time data monitoring and process control, enable manufacturers to maintain consistency in wire strength, surface finish, and dimensional accuracy, meeting the stringent requirements of various industries.Paragraph 6:With the growth of emerging technologies such as 5G, electric vehicles, and renewable energy systems, the demand for high-quality wires is on the rise. The Chinese high-speed straight wire drawing machine is perfectly positioned to cater to this increasing demand, offering a cost-effective solution without compromising on quality or productivity.Paragraph 7:The collaboration between the Chinese company and Square Wire Drawing Die also signifies the commitment to sustainable manufacturing practices. By reducing material wastage and optimizing energy consumption, the high-speed straight wire drawing machine contributes to a greener environment. This aspect aligns with global efforts to promote green manufacturing and sustainable industrial growth.Conclusion:The Chinese high-speed straight wire drawing machine, in collaboration with Square Wire Drawing Die, marks a significant breakthrough in the wire manufacturing industry. With its advanced technological capabilities, exceptional efficiency, and commitment to quality, the machine has the potential to transform wire manufacturing, meeting the increasing demands of various industries while contributing to sustainable industrial practices.

- 'New Screw Punch: The Latest Innovation in Construction Tools'

Screw Punch, a revolutionary new tool for the construction industry, has made waves in the market with its innovative design and unparalleled performance. Developed by a team of engineers and construction experts at {company}, Screw Punch has quickly gained a reputation as the go-to solution for all drilling and punching needs on construction sites.With its unique combination of power and precision, Screw Punch has set a new standard for efficiency and effectiveness in the industry. Its robust construction and heavy-duty design make it suitable for a wide range of applications, from basic drilling to more demanding tasks such as punching through tough materials like metal and concrete.The secret behind Screw Punch's exceptional performance lies in its advanced technology and engineering. The tool is powered by a high-torque motor that delivers the necessary power to punch through even the toughest materials with ease. Its precision-engineered drill bits ensure clean and accurate holes every time, saving time and effort on the job site.One of the key features that sets Screw Punch apart from other drilling tools on the market is its versatility. The tool comes with a range of interchangeable drill bits, allowing users to customize the tool to suit their specific drilling needs. Whether it's a small pilot hole or a larger bore, Screw Punch can handle it all with ease.In addition to its outstanding performance, Screw Punch also boasts a number of user-friendly features that make it a joy to use on the job site. The tool is ergonomically designed for comfort and ease of use, reducing operator fatigue during prolonged use. Its intuitive controls and easy-to-read display ensure that users can operate the tool with confidence and precision.Furthermore, Screw Punch is designed with safety in mind. The tool is equipped with a range of safety features, including overload protection and a safety clutch, to ensure the well-being of its users at all times. This makes Screw Punch not only a powerful and efficient tool, but also a safe and reliable one.The team at {company} is proud to have developed Screw Punch, and they are confident that the tool will continue to make a positive impact on the construction industry. "We saw a need for a drilling tool that could deliver exceptional performance in a wide range of applications, and we set out to create a solution that would exceed expectations," said a spokesperson for {company}. "Screw Punch represents the culmination of years of research, development, and testing, and we are thrilled to see it making a real difference for our customers in the field."The response from the construction industry has been overwhelmingly positive, with Screw Punch receiving high praise from contractors, builders, and construction professionals. Many have cited the tool's exceptional performance, versatility, and user-friendly design as key factors in their decision to adopt Screw Punch as their go-to drilling solution.Looking ahead, the team at {company} is already hard at work on the next generation of Screw Punch, with plans to further improve and enhance the tool's capabilities. With a commitment to continuous improvement and innovation, {company} is dedicated to ensuring that Screw Punch remains at the forefront of the construction industry for years to come.In conclusion, Screw Punch has quickly established itself as a game-changing tool for the construction industry, thanks to its exceptional performance, versatility, and user-friendly design. Developed by the team at {company}, Screw Punch is set to continue making a real difference for construction professionals across the world, as it sets a new standard for drilling and punching on the job site.

High-Quality Carbide Dies for Precision Manufacturing: A Complete Guide

Carbide Dies Unveils New Precision Tooling Technology to Enhance Manufacturing Efficiency{Company Name}, a leader in precision tooling technology, has announced the release of its latest product innovation, Carbide Dies. This cutting-edge tooling solution is designed to enhance manufacturing efficiency and accuracy, addressing the growing demand for high-quality precision tools in the industry.The new Carbide Dies technology features advanced carbide materials and innovative designs that offer superior performance and durability. With a focus on precision and reliability, these dies are engineered to meet the diverse needs of manufacturers across various industries, including automotive, aerospace, electronics, and more.One of the key benefits of Carbide Dies is its exceptional resistance to wear and corrosion, making it an ideal solution for high-volume production processes. This level of durability not only extends the lifespan of the tooling but also ensures consistent and reliable performance, resulting in cost savings and increased productivity for manufacturers.In addition to its durability, Carbide Dies also offers enhanced precision and accuracy, allowing for tight tolerances and complex geometries in the production of components. This level of precision is crucial in modern manufacturing processes, where the demand for high-quality parts continues to rise.With a dedicated team of engineers and technicians, {Company Name} has leveraged its extensive expertise in tooling technology to develop Carbide Dies as a cutting-edge solution that meets the evolving needs of the industry. The company's commitment to innovation and continuous improvement is evident in the development of this new product, which aims to set new benchmarks in precision tooling technology.The release of Carbide Dies comes at a time when manufacturers are increasingly seeking advanced tooling solutions to optimize their production processes and meet the growing demands of their customers. As industries continue to evolve and advance, the need for high-performance precision tools has become more critical than ever."We are excited to introduce Carbide Dies to the market, as we believe it will revolutionize the way manufacturers approach precision tooling," said {Spokesperson Name}, CEO of {Company Name}. "Our team has worked tirelessly to develop a product that not only meets the high standards of our industry but also exceeds the expectations of our customers. We are confident that Carbide Dies will make a significant impact in enhancing manufacturing efficiency and driving greater value for our customers."The launch of Carbide Dies further solidifies {Company Name}'s position as a leading provider of precision tooling solutions, with a strong focus on innovation, quality, and customer satisfaction. The company's commitment to delivering cutting-edge technologies that empower manufacturers to achieve new levels of performance and efficiency continues to drive its success in the industry.As the global manufacturing landscape continues to evolve, {Company Name} remains dedicated to staying at the forefront of technological advancements, while providing unparalleled support and expertise to its customers. The release of Carbide Dies is a testament to the company's unwavering commitment to driving innovation and delivering best-in-class solutions that address the evolving needs of the industry.With its launch, Carbide Dies is poised to make a significant impact in the manufacturing sector, offering a new standard of precision, durability, and performance that will undoubtedly set new benchmarks in the industry. As manufacturers seek to optimize their production processes and produce high-quality components, {Company Name} is proud to offer a cutting-edge solution that will empower them to achieve their goals with confidence and efficiency.

Latest innovation in fishing rods to hit the market

PUNCH ROD LAUNCHES NEW PRODUCT LINE, SET TO REVOLUTIONIZE THE INDUSTRYPunch Rod, a leading manufacturer in the industrial machinery sector, has announced the launch of a new product line that is set to revolutionize the industry. The company, which has been in operation for over 30 years, has built a reputation for delivering high-quality, innovative solutions for the manufacturing and production industries.The new product line is the result of years of research and development, and is designed to meet the increasing demands of modern manufacturing processes. With a focus on efficiency, reliability, and durability, the new products are expected to set a new standard for quality and performance in the industry.“The launch of our new product line marks an exciting milestone for Punch Rod. We have worked tirelessly to develop these new offerings, and we are confident that they will make a significant impact in the industry,” said the company’s CEO.The new line includes a range of innovative products, including advanced punching machines, rod bending equipment, and precision cutting tools. Each product is designed to meet the specific needs of modern manufacturing processes, and incorporates the latest advancements in technology and engineering.In addition to the new product line, Punch Rod has also announced a series of enhancements to its existing product range. These include updates to the company’s popular line of CNC punching machines, as well as improvements to its rod bending and cutting equipment.“As a company, we are committed to staying ahead of the curve and providing our customers with the most advanced solutions available. The enhancements to our existing product range, alongside the launch of our new line, reflect this commitment,” the CEO added.Punch Rod’s products are used in a wide range of industries, including automotive, aerospace, and construction. The company’s reputation for quality and reliability has made it a trusted partner for businesses around the world, and the launch of the new product line is expected to further cement its position as a leader in the industry.“We have already received a tremendous amount of interest in our new products, and we are confident that they will be well-received in the market. We look forward to seeing the impact that they will have on the industry as a whole,” the CEO said.Punch Rod’s commitment to innovation and excellence has helped it to become a trusted name in the industrial machinery sector. With the launch of its new product line, the company is poised to set a new standard for quality and performance in the industry, and to continue to meet the evolving needs of modern manufacturing processes.