How Small Screws Header Punches Are Used in Manufacturing Processes

By:Admin

In the world of precision manufacturing, the importance of small screws cannot be overstated. These tiny, often overlooked components play a crucial role in the functioning of countless devices and machines. As such, the process of manufacturing small screws requires a high level of precision and accuracy. This is where Small Screws Header Punch comes into play.

Small Screws Header Punch is a leading manufacturer of precision tooling and machinery for the production of small screws. With years of experience and a dedication to excellence, Small Screws Header Punch has earned a stellar reputation in the industry for providing high-quality, reliable products that meet the exacting needs of their customers.

The company's range of products includes header punches, thread rolling dies, and other essential tools for the production of small screws. These tools are designed and manufactured with the utmost attention to detail, ensuring that they meet the strictest quality standards. Small Screws Header Punch's commitment to excellence is reflected in the precision and durability of their products, making them a go-to choice for manufacturers seeking to produce top-quality small screws.

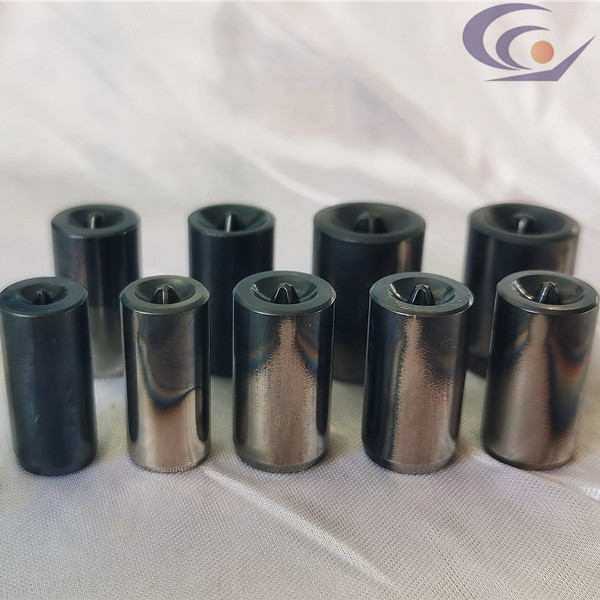

One of the company's standout products is their Small Screws Header Punch, which is designed to meet the specific demands of small screw manufacturing. This tool is engineered to deliver precise and consistent results, making it an indispensable asset for any manufacturer involved in the production of small screws. Its durable construction and advanced technology ensure that it can withstand the rigors of high-volume production, making it a reliable and cost-effective solution for manufacturers.

The Small Screws Header Punch is equipped with advanced features that set it apart from the competition. Its precision-ground punch point and custom-designed geometry enable it to produce small screws with unmatched accuracy and consistency. This level of precision is crucial in ensuring that the small screws produced meet the exact specifications required for their intended applications.

In addition to its exceptional performance, the Small Screws Header Punch is also designed with user convenience in mind. Its ergonomic design and intuitive controls make it easy to operate, reducing the risk of operator error and increasing productivity. This makes it an ideal choice for manufacturers looking to streamline their small screw production processes.

Small Screws Header Punch is also committed to providing superior customer support, offering comprehensive training and technical assistance to ensure that their customers can make the most of their products. This dedication to customer satisfaction has earned Small Screws Header Punch a loyal and satisfied customer base, further solidifying its position as a leader in the precision tooling industry.

As the demand for small screws continues to grow across various industries, the need for reliable and efficient manufacturing solutions is more critical than ever. Small Screws Header Punch is at the forefront of meeting this demand, providing manufacturers with the tools they need to produce small screws with unmatched precision and consistency.

In conclusion, Small Screws Header Punch is a trusted name in the world of precision tooling, and their Small Screws Header Punch stands as a testament to their commitment to excellence. With its advanced features, superior performance, and dedication to customer satisfaction, Small Screws Header Punch is an indispensable partner for manufacturers seeking to achieve the highest standards in small screw production.

Company News & Blog

Ultimate Guide to Roll Forming Die Design for Precision Manufacturing

Roll Forming Die Design is an essential process in the production of custom roll-formed parts. It involves the creation of a tool that carries out the roll forming process, which shapes metal into desired profiles. The design of the roll forming die plays a crucial role in ensuring the accuracy, efficiency, and quality of the final product. With the right die design, manufacturers can achieve precise and consistent forming of materials, resulting in high-quality products.One company that has excelled in roll forming die design is {}. They have established themselves as a leading provider of custom roll-formed parts and have built a strong reputation for their expertise in die design. With a focus on innovation and precision, they have developed cutting-edge die designs that have set them apart in the industry.The company's die design process begins with a thorough analysis of the customer's requirements and specifications. Their team of skilled engineers and technicians work closely with the customer to understand their needs and design a die that meets their exact requirements. Using advanced software and tools, they create and test multiple iterations of the die design to optimize its performance and ensure its compatibility with the roll forming equipment.One of the key factors that sets {} apart in roll forming die design is their commitment to innovation. They continuously invest in research and development to stay ahead of the curve and incorporate the latest technologies and techniques into their die design process. This dedication to innovation has enabled them to produce highly efficient and precise die designs that deliver exceptional results for their customers.In addition, {} is known for its dedication to quality and precision. They adhere to strict quality control measures throughout the die design and manufacturing process to ensure that the final product meets the highest standards. Their state-of-the-art manufacturing facility is equipped with the latest machinery and technology, allowing them to produce dies with exceptional accuracy and consistency.Furthermore, the company's extensive experience in roll forming die design sets them apart as a trusted partner for customers in a wide range of industries. Whether it's automotive, construction, or aerospace, {} has the expertise to design and manufacture dies for various applications and industries. Their ability to tailor die designs to specific requirements has earned them the trust and loyalty of numerous customers over the years.With a focus on innovation, quality, and precision, {} has established itself as a leader in roll forming die design. Their commitment to meeting customer needs and delivering superior products sets them apart in the industry. As they continue to push the boundaries of roll forming die design, they are poised to remain a top choice for companies seeking high-quality custom roll-formed parts.

Ultimate Guide to Roll Forming Die: Everything You Need to Know

Roll Forming Die: A Key Component in Manufacturing ProcessIn the world of manufacturing, precision and efficiency are crucial aspects to consider in the production process. One important component that plays a vital role in achieving these goals is the roll forming die. A roll forming die is a tool used in the roll forming process to shape metal sheets and coils into desired profiles and shapes. It is a key element in the manufacturing of a wide range of products, including automotive parts, solar panels, building materials, and more.The roll forming process itself is a continuous bending operation in which a long strip of metal is passed through consecutive sets of rolls, each set performing incremental bending operations to gradually shape the metal into the desired profile. The roll forming die is used to form the metal by applying pressure and guiding it through the various stages of the roll forming process. The precision and accuracy of the roll forming die directly impact the quality and integrity of the final product.At {}, we specialize in the design and manufacturing of high-quality roll forming dies for a diverse range of industries. With over 20 years of experience in the industry, we have established ourselves as a leading provider of roll forming solutions, offering our customers innovative die designs and top-notch manufacturing capabilities.Our team of engineers and technicians are highly skilled and experienced in the design and production of roll forming dies. We utilize the latest technology and equipment to ensure that our dies meet the highest standards of quality and performance. From initial concept to final production, we work closely with our customers to understand their specific requirements and to develop custom die solutions that meet their unique needs.As a customer-focused company, we are committed to delivering exceptional value and service to our clients. We understand the importance of efficiency and reliability in the manufacturing process, and strive to provide roll forming dies that optimize production output and minimize downtime. Our dedication to quality and continuous improvement has earned us the trust and loyalty of our customers, who rely on us to deliver superior roll forming die solutions time and time again.In addition to our expertise in roll forming die design and manufacturing, we also offer comprehensive support services to assist our customers throughout the entire lifecycle of their dies. From installation and training to maintenance and repair, our team is dedicated to ensuring that our customers get the most out of their roll forming dies.With a focus on innovation and excellence, we continue to invest in research and development to further enhance our capabilities and expand our range of roll forming solutions. We are committed to staying at the forefront of industry trends and technological advancements, so that we can offer our customers the most advanced and reliable roll forming die solutions available.In conclusion, the roll forming die is an essential component in the manufacturing process, and plays a critical role in shaping metal into a wide variety of profiles and products. As a leading provider of roll forming die solutions, {} is dedicated to delivering high-quality, innovative, and reliable die designs that meet the unique needs of our customers. With our commitment to excellence and customer satisfaction, we are proud to be a trusted partner in the success of businesses across the globe.

High-quality Carbide Punch and Die for Superior Performance: A Guide

Carbide Punch and Die Revolutionizing Industrial Manufacturing ProcessesCarbide Punch and Die, a leading manufacturer and supplier of high-quality carbide tools, is making waves in the industrial manufacturing sector with its innovative products and services. With an extensive range of carbide punches and dies, the company is helping businesses achieve unparalleled precision, efficiency, and durability in their production processes.Established over two decades ago, Carbide Punch and Die has cemented its position as a trusted name in the industry. The company's commitment to excellence is evident in its state-of-the-art manufacturing facilities, cutting-edge technology, and highly skilled workforce. These factors have allowed Carbide Punch and Die to offer a diverse range of products that cater to various industries, including automotive, aerospace, electronics, medical, and more.One of the company's standout products is its carbide punches. These punches are made from a combination of tungsten carbide, cobalt, and other high-grade materials, ensuring exceptional hardness, toughness, and resistance to wear. Carbide punches are widely used in punching applications, such as creating holes, notches, and other customized shapes in various materials like sheet metal, plastics, and wood.Carbide Punch and Die's carbide punches offer numerous advantages over traditional steel punches. Firstly, the exceptional hardness of carbide punches allows for a longer tool life and extended intervals between tool replacements. This significantly reduces downtime and maintenance costs for businesses, increasing overall productivity and profitability.Moreover, the superior wear resistance of carbide punches ensures consistent and precise results even after prolonged usage. This enhances the accuracy and quality of the end product, ultimately leading to customer satisfaction. Carbide punches also exhibit excellent thermal stability, preventing heat-induced deformation during demanding manufacturing processes.In addition to carbide punches, Carbide Punch and Die specializes in manufacturing carbide dies. These dies are used in various applications, including stamping, cutting, and forming operations. Carbide dies offer exceptional durability and reliability, as they can withstand high-temperature and high-pressure conditions without compromising on performance.Furthermore, Carbide Punch and Die's expertise in carbide tool production extends beyond punches and dies. The company also offers a range of carbide wear parts, such as bushings, inserts, and nozzles, which are crucial components in industries like oil and gas, mining, and construction. These wear parts are known for their exceptional resistance to abrasion, erosion, and corrosion, ensuring longevity and cost-effectiveness.Carbide Punch and Die's success can be attributed to its commitment to customer satisfaction. The company works closely with clients to understand their unique requirements and tailor solutions to meet their exact needs. This collaborative approach, combined with the company's technical expertise, allows Carbide Punch and Die to develop customized carbide tooling solutions that optimize productivity and minimize costs for its customers.As a testament to its quality and reliability, Carbide Punch and Die has received numerous certifications and accolades, including ISO 9001:2015 certification and recognition as a preferred supplier by leading manufacturing companies. These achievements validate the company's continuous efforts to deliver superior products and services.Carbide Punch and Die's constant dedication to innovation and excellence positions it as an industry leader in carbide tool manufacturing. With its wide range of carbide punches, dies, and wear parts, the company is revolutionizing the way industrial manufacturing processes are conducted, offering businesses unmatched precision, efficiency, and durability.In conclusion, Carbide Punch and Die's cutting-edge products, state-of-the-art facilities, and commitment to customer satisfaction have propelled it to the forefront of the carbide tooling industry. With its innovative solutions, the company continues to empower businesses with the tools they need to achieve remarkable results in their manufacturing processes.

Top Picks for Screw Extractor Drill Bits: Find the Perfect Fit for Your Needs

Screw Extractor Drill Bits: Choosing the Best for Your NeedsWhen it comes to removing stubborn, damaged, or rusted screws, having the right tool is essential. This is where screw extractor drill bits come into play. With their unique design and functionality, these tools are designed to effortlessly remove any troublesome screws. In this blog, we will guide you through the process of choosing the best screw extractor drill bits for your needs, discussing various types, models, and sizes available on the market.Types of Screw Extractor Drill BitsThere are several different types of screw extractor drill bits available, each offering different benefits and advantages. Let's take a closer look at the most common types:1. Spiral Flute Extractor Drill Bits: These are the most popular and versatile type of screw extractor drill bits. They feature twisted flutes that create a gripping action, enabling them to remove screws with ease.2. Double-Ended Extractor Drill Bits: These drill bits have two ends, each designed with a different size of screw extractor. This makes them highly efficient for tackling a wide range of screw sizes. They are ideal for those who frequently deal with various-sized screws.3. Multi-Spline Extractor Drill Bits: Multi-spline extractor drill bits have a unique design with multiple splines on one end. These splines fit into the screw head, providing a strong grip for quick and easy extraction. They are particularly effective when dealing with stripped or damaged screws.4. Straight Flute Extractor Drill Bits: Unlike spiral flute extractor drill bits, straight flute ones have a flatter design. They work well for removing screws embedded deep within the material, ensuring a secure and damage-free removal process.Choosing the Right Model and SizeOnce you've determined the type of screw extractor drill bit you need, it's important to choose the right model and size for your specific application. Consider the following factors:1. Material: Look for screw extractor drill bits made from high-quality materials such as high-speed steel (HSS) or cobalt steel. These materials offer durability and resistance to wear and tear, ensuring a long lifespan for your tool.2. Compatibility: Ensure that the screw extractor drill bit you choose is compatible with your drill. Most extractor bits have a standard hex shank, fitting most drills, but it's always a good idea to double-check before making a purchase.3. Size Range: Different screw extractor drill bits come in various sizes, allowing you to extract screws of different diameters. Consider the range of sizes you typically work with to ensure that the chosen bit will cover your needs.Keyword Inclusion:While ensuring thorough and informative content, it's essential to incorporate relevant keywords to optimize this blog for search engine optimization (SEO). Some of the keywords that may help improve visibility are "Drill Screw," "Header Punch," and "Screw Extractor Drill Bits." Utilizing these keywords naturally throughout the blog will increase the chances of it appearing in search engine results.ConclusionChoosing the right screw extractor drill bit can make a significant difference when it comes to removing stubborn, damaged, or rusted screws. With the wide range of options available, considering the type, model, and size of the drill bit is essential. By selecting the appropriate tool for your needs, you can save time, effort, and frustration in the removal process. Keep in mind the keywords mentioned, and ensure that the blog provides the necessary information to guide users in their selection of the best screw extractor drill bits.

Precision Die Trimming for CVD Materials: A Complete Guide

Cvd Trimmingd Die revolutionizes die trimmingThe die trimming industry is experiencing a revolution with the introduction of Cvd Trimmingd Die, a groundbreaking technology that is set to change the way die trimming is done. Developed by a leading industry player, this cutting-edge technology is expected to bring about significant improvements in terms of precision, speed, and efficiency in die trimming processes.Cvd Trimmingd Die is a result of years of extensive research and development by a team of highly experienced engineers and experts in the field of die trimming. The technology is designed to address the limitations and challenges that have long been associated with traditional die trimming methods. By leveraging advanced materials and innovative design concepts, Cvd Trimmingd Die is able to deliver superior performance and exceptional results in die trimming applications.One of the key features of Cvd Trimmingd Die is its precision and accuracy. The technology is engineered to provide ultra-precise trimming of dies, ensuring that the final product meets the most stringent quality standards. This level of precision is made possible by the use of state-of-the-art CNC machining techniques and advanced metrology systems, which enable the technology to achieve sub-micron accuracy in die trimming operations.In addition to precision, Cvd Trimmingd Die also offers significant improvements in terms of speed and efficiency. The technology is capable of performing die trimming at a much faster rate compared to traditional methods, thereby reducing lead times and increasing overall productivity. This is achieved through the use of high-speed cutting tools and optimized cutting parameters, which allow for rapid and efficient removal of excess material from dies.Furthermore, Cvd Trimmingd Die is designed to be highly versatile and adaptable to a wide range of die trimming applications. Whether it is for the aerospace, automotive, medical, or electronics industry, this technology can be customized to meet the specific needs of different sectors. Its flexibility and versatility make it an ideal solution for manufacturers and fabricators looking to enhance their die trimming capabilities.With its introduction, Cvd Trimmingd Die is expected to have a significant impact on the die trimming industry. Manufacturers and fabricators will now have access to a state-of-the-art technology that offers unprecedented levels of precision, speed, and efficiency in die trimming. This is poised to result in improved product quality, reduced production costs, and faster time-to-market for a wide range of products.The company behind Cvd Trimmingd Die is a well-established industry leader with a strong track record of delivering innovative solutions for the manufacturing and fabrication sectors. With a focus on continuous improvement and a commitment to excellence, the company has earned a reputation for being a trusted partner for businesses looking to enhance their manufacturing capabilities.In conclusion, the introduction of Cvd Trimmingd Die marks a significant milestone in the die trimming industry. This cutting-edge technology is set to revolutionize the way die trimming is done, offering unparalleled levels of precision, speed, and efficiency. With its potential to deliver superior results and drive innovation in manufacturing and fabrication, Cvd Trimmingd Die is poised to become the technology of choice for die trimming applications across various industries.

Ultimate Guide to Circular Thread Rolling Dies

Circular Thread Rolling DiesCircular thread rolling dies are an essential tool for creating precise and high-quality threads on a variety of materials. These dies are commonly used in the automotive, aerospace, and machinery industries to produce strong and reliable threads in nuts, bolts, screws, and other components.{Company name} is a leading manufacturer of circular thread rolling dies, with a strong reputation for producing high-quality and durable tools. With over 20 years of experience in the industry, {Company name} has become a trusted name for businesses looking for reliable thread rolling solutions.The circular thread rolling dies produced by {Company name} are designed to meet the highest industry standards, with a focus on precision, durability, and performance. These dies are engineered using advanced manufacturing techniques and high-quality materials to ensure consistent and accurate threading results.{Company name} offers a comprehensive range of circular thread rolling dies, including standard and custom designs to meet the specific requirements of each customer. Whether it's for small batch production or high-volume manufacturing, {Company name} has the expertise and capability to provide the right threading solution for every application.In addition to its extensive product lineup, {Company name} also offers technical support and consultation services to help customers optimize their thread rolling processes. The company's team of experienced engineers and technicians can provide valuable insights and recommendations to improve thread quality, reduce production time, and enhance overall efficiency.One of the key advantages of choosing {Company name}'s circular thread rolling dies is the company's commitment to continuous innovation and improvement. {Company name} invests heavily in research and development to stay ahead of industry trends and technology advancements, ensuring that its products remain at the forefront of the market.Moreover, {Company name} places a strong emphasis on quality control and testing to guarantee the reliability and durability of its circular thread rolling dies. The company follows strict quality assurance protocols and standards to deliver tools that meet or exceed customer expectations.As part of its commitment to sustainability and environmental responsibility, {Company name} also focuses on eco-friendly manufacturing processes and materials. By minimizing waste and reducing energy consumption, {Company name} strives to make a positive impact on the environment while maintaining its high standards of product quality.With a strong global presence, {Company name} serves customers across various industries and markets, delivering circular thread rolling dies that are trusted for their performance, longevity, and cost-effectiveness. The company's dedication to customer satisfaction and product excellence has earned it a loyal customer base and a reputation as a dependable partner for thread rolling solutions.In conclusion, {Company name} stands out as a leading manufacturer of circular thread rolling dies, offering a comprehensive range of high-quality products and technical support services. With a focus on precision, innovation, and sustainability, {Company name} continues to be a preferred choice for businesses seeking reliable thread rolling solutions for their manufacturing needs.

Revolutionary Screw Making Machine Shakes Up Chinese Manufacturing Industry

China Screw Making Machine Revolutionizes the Manufacturing IndustryChina has long been known for its prowess in manufacturing, and its latest innovation, the Screw Making Machine, is set to revolutionize the industry. This advanced machinery, developed by a leading Chinese company, boasts cutting-edge technology and promises improved efficiency and precision in screw production. With its remarkable capabilities, the Screw Making Machine is anticipated to have a significant impact not only in China but also globally, further establishing China as a key player in the manufacturing sector.The Screw Making Machine, with its state-of-the-art design and functional features, is set to enhance the manufacturing process. Leveraging the power of automation, the machine streamlines the production of screws, allowing for increased output and reduced human error. By automating repetitive tasks, the Screw Making Machine eliminates the need for manual labor, making the manufacturing process faster and more efficient. This innovation aligns with China's ongoing efforts to transition towards smart manufacturing and technological advancements.In addition to its increased efficiency, the Screw Making Machine also boasts impressive precision and accuracy. The machine's advanced software and computer-controlled system ensure consistent quality, producing screws with exact specifications every time. This level of precision is crucial, as screws play a vital role in various industries, including automotive, electronics, and construction. With the ability to produce screws tailored to specific needs, the Screw Making Machine enables manufacturers to meet the rigorous standards demanded by today's global market.Moreover, this innovative technology is highly customizable, allowing manufacturers to adapt the machine according to their specific requirements. With various adjustable settings and parameters, the Screw Making Machine offers flexibility, catering to the diverse needs of different industries. This adaptability ensures that the machine can be integrated seamlessly into existing manufacturing processes, without disrupting workflow or productivity. As a result, companies can harness the benefits of the Screw Making Machine without facing significant challenges in implementation.The Screw Making Machine is not only a testament to China's manufacturing capabilities but also a reflection of the country's commitment to sustainability. This advanced machinery incorporates eco-friendly features, reducing energy consumption and minimizing waste. By optimizing the manufacturing process, the machine strives to reduce environmental impact, meeting the growing demand for sustainable production practices. This focus on sustainability aligns with the global shift towards green manufacturing, ensuring that China remains at the forefront of industry trends.The introduction of the Screw Making Machine has sparked excitement within the manufacturing industry, both in China and worldwide. Manufacturers are eager to leverage the machine's capabilities to enhance productivity, efficiency, and quality control. With its potential to optimize existing processes and increase output, the Screw Making Machine is poised to bolster the competitiveness of Chinese manufacturers in the global arena.In conclusion, the Screw Making Machine developed by this leading Chinese company represents a significant advancement in the manufacturing industry. With its automation, precision, flexibility, and sustainability, this ground-breaking technology has the potential to transform the production of screws. China's continued commitment to innovation and technological advancement ensures that the country remains a force to be reckoned with in the manufacturing sector. As manufacturers worldwide embrace this revolutionary machinery, the Screw Making Machine is set to redefine the standards of screw production and solidify China's position as a global manufacturing leader.

- 'New Screw Punch: The Latest Innovation in Construction Tools'

Screw Punch, a revolutionary new tool for the construction industry, has made waves in the market with its innovative design and unparalleled performance. Developed by a team of engineers and construction experts at {company}, Screw Punch has quickly gained a reputation as the go-to solution for all drilling and punching needs on construction sites.With its unique combination of power and precision, Screw Punch has set a new standard for efficiency and effectiveness in the industry. Its robust construction and heavy-duty design make it suitable for a wide range of applications, from basic drilling to more demanding tasks such as punching through tough materials like metal and concrete.The secret behind Screw Punch's exceptional performance lies in its advanced technology and engineering. The tool is powered by a high-torque motor that delivers the necessary power to punch through even the toughest materials with ease. Its precision-engineered drill bits ensure clean and accurate holes every time, saving time and effort on the job site.One of the key features that sets Screw Punch apart from other drilling tools on the market is its versatility. The tool comes with a range of interchangeable drill bits, allowing users to customize the tool to suit their specific drilling needs. Whether it's a small pilot hole or a larger bore, Screw Punch can handle it all with ease.In addition to its outstanding performance, Screw Punch also boasts a number of user-friendly features that make it a joy to use on the job site. The tool is ergonomically designed for comfort and ease of use, reducing operator fatigue during prolonged use. Its intuitive controls and easy-to-read display ensure that users can operate the tool with confidence and precision.Furthermore, Screw Punch is designed with safety in mind. The tool is equipped with a range of safety features, including overload protection and a safety clutch, to ensure the well-being of its users at all times. This makes Screw Punch not only a powerful and efficient tool, but also a safe and reliable one.The team at {company} is proud to have developed Screw Punch, and they are confident that the tool will continue to make a positive impact on the construction industry. "We saw a need for a drilling tool that could deliver exceptional performance in a wide range of applications, and we set out to create a solution that would exceed expectations," said a spokesperson for {company}. "Screw Punch represents the culmination of years of research, development, and testing, and we are thrilled to see it making a real difference for our customers in the field."The response from the construction industry has been overwhelmingly positive, with Screw Punch receiving high praise from contractors, builders, and construction professionals. Many have cited the tool's exceptional performance, versatility, and user-friendly design as key factors in their decision to adopt Screw Punch as their go-to drilling solution.Looking ahead, the team at {company} is already hard at work on the next generation of Screw Punch, with plans to further improve and enhance the tool's capabilities. With a commitment to continuous improvement and innovation, {company} is dedicated to ensuring that Screw Punch remains at the forefront of the construction industry for years to come.In conclusion, Screw Punch has quickly established itself as a game-changing tool for the construction industry, thanks to its exceptional performance, versatility, and user-friendly design. Developed by the team at {company}, Screw Punch is set to continue making a real difference for construction professionals across the world, as it sets a new standard for drilling and punching on the job site.

High-Quality Truss Head Screw Header Punch for Precision Fastening

Truss Head Screw Header Punch Revolutionizes the Fastener IndustryThe fastener industry has seen a significant advancement with the introduction of the Truss Head Screw Header Punch by a leading company in the field. This innovative product has brought about a revolution in the way truss head screws are manufactured, offering various benefits to the industry and its consumers.The company is a renowned name in the fastener industry, specializing in the production of high-quality machinery and equipment. With a strong emphasis on research and development, the company has consistently introduced cutting-edge technologies to cater to the evolving needs of the industry.The Truss Head Screw Header Punch is the latest addition to the company's product portfolio, designed to enhance the production process of truss head screws. The truss head screw is a popular fastener used in various applications, known for its wide and low-profile head, which provides a large bearing surface and prevents over-tightening during installation.The header punch is an essential component in the manufacturing of truss head screws, responsible for shaping the head of the screw during the production process. The Truss Head Screw Header Punch has been engineered to deliver superior performance, offering unmatched precision and efficiency in the production of truss head screws.One of the key features of the Truss Head Screw Header Punch is its ability to produce consistent and uniform screw heads, ensuring high-quality and reliable fasteners. This level of precision is essential in meeting the stringent requirements of various industries, including automotive, construction, and aerospace, where truss head screws are widely used.Furthermore, the Truss Head Screw Header Punch is capable of enhancing the production output of truss head screws, thanks to its high-speed operation and minimal downtime. This allows manufacturers to increase their productivity and meet the growing demand for truss head screws in the market.In addition to its performance benefits, the Truss Head Screw Header Punch also offers a user-friendly design, incorporating advanced features that make it easy to operate and maintain. This not only improves the overall efficiency of the manufacturing process but also reduces the likelihood of errors and inconsistencies in the production of truss head screws.The introduction of the Truss Head Screw Header Punch has been well-received by the fastener industry, with many manufacturers recognizing its potential to drive innovation and improve their operations. The product has already garnered significant interest from key players in the industry, with several companies expressing their intent to integrate this technology into their production facilities.Moreover, the company behind the Truss Head Screw Header Punch has demonstrated its commitment to providing comprehensive support to its customers, offering technical assistance and training to ensure the seamless integration of the product into their manufacturing processes. This further underscores the company's dedication to delivering value beyond its innovative products.Overall, the Truss Head Screw Header Punch represents a significant advancement in the fastener industry, offering a solution that addresses the evolving needs of manufacturers and consumers alike. With its precision, efficiency, and user-friendly design, this product is set to redefine the production of truss head screws and elevate the standards of quality in the industry. As the company continues to drive innovation, it is likely that we will see further advancements that will shape the future of the fastener industry.

Header Punch for Wood Screws: A Useful Tool for DIY Projects

Wood Screws Header Punch, a leading manufacturer in the hardware industry, has recently introduced a revolutionary new product that is set to change the game for the wood screws market. The company, known for its innovative and high-quality products, has once again proven its dedication to providing top-notch solutions for the construction and woodworking industry.Wood Screws Header Punch has been a key player in the hardware industry for over two decades, with a strong focus on producing a wide range of fasteners, including screws, nails, and bolts. The company has built a solid reputation for its commitment to precision, reliability, and durability in all of its products. With state-of-the-art manufacturing facilities and a team of skilled engineers, Wood Screws Header Punch has consistently delivered exceptional products that meet the needs of its customers.The new product from Wood Screws Header Punch is a game-changer for the wood screws market. This innovative header punch is designed to provide superior performance and efficiency when it comes to driving wood screws into various materials. With its advanced design and engineering, this header punch ensures that wood screws are securely and precisely driven, reducing the risk of stripping or damaging the screws during installation.One of the key features of the Wood Screws Header Punch is its compatibility with a wide range of wood screws, making it a versatile tool for different woodworking applications. Whether it's for furniture making, cabinetry, or general woodworking projects, this header punch can handle various sizes and types of wood screws with ease and precision. This versatility makes it a must-have tool for professionals and enthusiasts alike.In addition to its compatibility, the Wood Screws Header Punch boasts a user-friendly design that makes it easy to use for individuals of all skill levels. Its ergonomic handle and lightweight construction ensure that users can operate the header punch comfortably and efficiently, reducing fatigue during extended use. This attention to detail in the design reflects Wood Screws Header Punch's commitment to providing practical and user-friendly solutions for its customers.Furthermore, the Wood Screws Header Punch is constructed with high-quality materials to ensure long-lasting durability and reliability. The company's dedication to producing top-notch products is evident in the meticulous attention to detail and rigorous quality control processes implemented in the manufacturing of this header punch. Customers can trust that they are investing in a tool that will stand the test of time and deliver consistent performance throughout its lifespan.The introduction of the Wood Screws Header Punch is a testament to Wood Screws Header Punch's ongoing commitment to innovation and excellence in the hardware industry. By providing a revolutionary solution for driving wood screws, the company is once again setting a new standard for quality and performance.Wood Screws Header Punch has built a strong reputation as a trusted and reliable manufacturer in the hardware industry. Its dedication to precision, reliability, and quality has made it a go-to choice for professionals and enthusiasts alike. With the introduction of the Wood Screws Header Punch, the company continues to solidify its position as a leader in the market, delivering innovative solutions that meet the needs of its customers.As the demand for high-quality fasteners continues to grow, Wood Screws Header Punch remains at the forefront of the industry, consistently providing top-notch products that exceed customer expectations. The introduction of the Wood Screws Header Punch is a testament to the company's commitment to innovation and its ability to continually raise the bar for quality and performance in the hardware industry. With this revolutionary new product, Wood Screws Header Punch is once again demonstrating its dedication to driving progress and excellence in the market.